The population of Colombo is increasing at a staggering pace. With new urbanisation underway, an innovative drainage and sewer project is taking place within the city, reports Harin Fernando.

A survey of Colombo sewer pipes, carried out seven years ago, revealed an urgent need to have the pipes rehabilitated. The National Water Supply and Drainage Board gave the contract to rehabilitate the main sewer system in Colombo to Danish contracting group Per Aarsleff A/S. The Project Manager, Martin Rye Andersen, said “that the need to rehabilitate the system has existed for a long time. “The pipes are almost 100 years old. Any pipeline has to have rehabilitation. So it was decided to take the most critical pipelines, those leading to the main pumping station in Colombo, and apply remedial action.”

This action is a Rs2.5 billion project that involves the rehabilitation of nearly 10km of sewer pipeline, without digging trenches to access the pipes, thereby minimising inconvenience to road users. The establishment of a new pumping station, and the renovation of an existing pumping station at Madampitiya, is also part of the project. Attention to the sewer pipes were needed not just because of a lack of maintenance, but also because the sewer network capacity is stretched to its capacity. Colombo’s low altitude, although above sea level, results in the retention of ground water in the soil. This means that when a pipe becomes defective the ground water seeps in. This is followed by the surrounding soil and eventually leads to pipe and system collapses, as seen recently in Maradana. The contract to rehabilitate the over-stressed system is financed by the Danish International Development Agency (DANIDA), and is the first under their mixed credit programme to Sri Lanka. The project is to be implemented over a period of 32 months; having commenced in March 2005, work is on target to be completed by November 2007. Working in Sri Lanka has not been without its fair share of problems, according to the Project Manager.

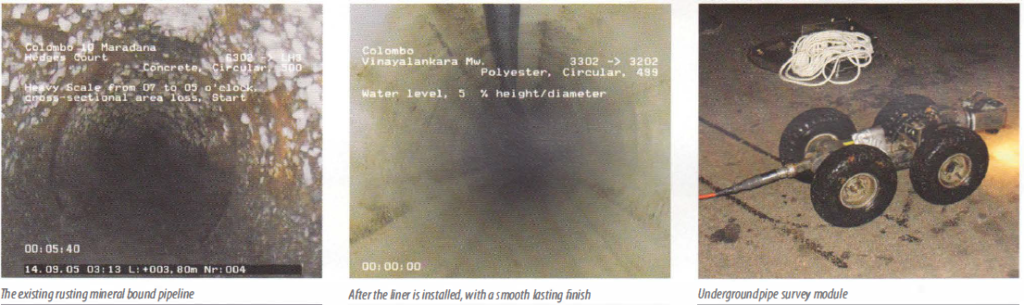

“In a project of this scale there are always some obstacles. This is the first contract we have in Sri Lanka. Working here is fairly similar to working in India, the system is pretty much the same, both are old British colonies with all the good and bad things from the British. So it comes as no surprise that getting permits and working with the Water Board is pretty much the same as it was in India. It takes time for decisions to be made and traditional inbuilt unavoidable red tape does sometimes get in the way.” Apart from coping with bureaucracy, the project is proceeding according to established engineering principles. Pipe rehabilitation without digging trenches involves the feeding of a specially-prepared liner into the existing sewer lines and then following a curing process of jetting hot water into it. The liner attaches itself, covering the existing passage and forming a new one. The liner is installed from a scaffold over an existing manhole. It is inverted in soft condition into the defective pipe by means of water pressure. The liner attaches itself, covering the existing passage and forming a new pipe. Once it is in place and cured it becomes hard and abrasion-resistant with a smooth surface. The work is carried out mainly at night with the contractors working under bright floodlight . They work as a team in order to complete work on each section before traffic builds up as the city wakes. When the installation is undertaken, existing sewer lines are diverted. The Colombo pipe system consists of circular and egg-shaped pipes dimensioned 450mm and 1830x1220mm respectively. The rehabilitation methods being applied include traditional Aarsleff Tube lining, as well as lining the pipes with prefabricated glass fibre elements.

The Aarsleff liner is made at a plant in Wattala of acid-proof polyester fibre impregnated with resin. The liner is produced in all lengths and wall thicknesses and can be sewn together, enabling pipe stretches of different dimensions to be rehabilitated in one run. Thus it is possible to rehabilitate several hundred metres at a time. Once the chemical impregnation has occurred, the pipe must be transported at low temperatures, to which end ice is being used as a coolant. Geographically, Colombo being wry flat, the lope of the piping is limited. When the rehabilitation i completed, the Colombo Municipal Council will be in charge of maintenance. Staff will be trained. According to the Project Manager, given the low slope, the risk of sedimentation is the biggest threat, but is fairly simple to get rid of. The new liner sections are expected to be good for use for another 50 years. This also means that current capacity can be increased by up to 10%, in keeping with anticipated population growth.