Since its humble beginnings with a single small factory the Upasena family has flourished in leaps and bounds over the years. Today the Group has progressed remarkably to become one of the foremost tea producers in all of Asia. Presently, it is only Saman Upasena and his brother Thusan Upasena at the helm, but they’ve managed to continue innovating and earning accolades for the KDU Group, all the while never losing touch with the family-spirit and hands-on approach that Saman Upasena credits as the recipe for their success.

By Ben Fowler

Photography Indika De Silva

The patriarch, K D Upasena, after considerable success in the gem industry (notably for introducing the “gemming diving kit” to Sri Lanka) entered the tea business by leasing the Maha Kade Istoruwa factory. In 1982 he purchased it outright, and ever since it has been known as the Galpaditenna Tea Factory, which today boasts an astounding annual production of over three million kilos of Orthodox Tea – an accomplishment that continues to earn much recognition.

Orthodox Tea, for what Sri Lanka is renowned, favours climate conditions in the low country. There is where the elder Upasena wasted no time establishing his empire – by the time his sons joined the business in 1990 he was in charge of seven factories. From 1992 onwards, the Upasena family produced not only the highest amount of Orthodox Tea in Sri Lanka, but in all of Asia – a mere decade after Upasena purchased Galpaditenna.

“My father passed away in 2001 and thereafter my mother was the chairperson of the group. We hold eight tea factories and go as the KDU group,” said Saman Upasena Managing Director/Partner – KDU Group, the acronym of which honours his father’s initials. Saman, who was persuaded by his father to join the business as a 22-year old, became a natural through his hands-on experience.

“That is where our success is. Even the brokers and buyers all know the personal involvement by the group that goes into the calibration and other processes,” he remarked, regarding the Group’s work ethic. He describes his personal inclination towards holistic involvement in tea manufacturing, “like bread and butter”.

This work ethic that has been fostered is apparent in their business model as well. And incidentally, the Group would rather directly deal with the 22,000 small holders who provide them with the green leaves than hire a middleman.

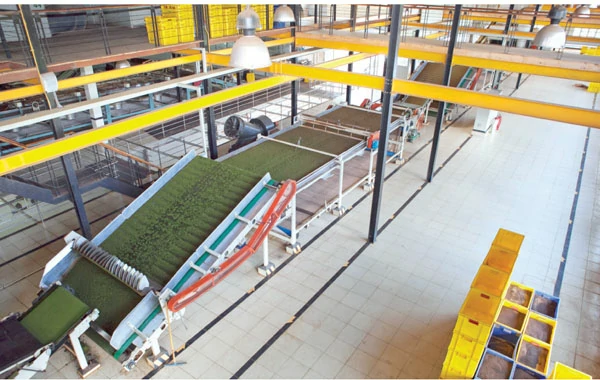

Among the many contributions to the KDU legacy and perhaps its single most important, is the addition of automation, which has played no small role in increasing the factory’s output to over three million kilos a year. “We were the first to start automation. Earlier, Orthodox Tea was a man-handled product and not too hygienic.” Automation has also increased efficiency and streamlined its functions resulting in consistent packaging, helping simplify trade and limiting enormous operation needs including manpower. Consequently the Galpaditenne Factory has over the past 17 consecutive years achieved the highest production volume not only in Sri Lanka but Asia as well. With their upward momentum in efficiency, this year they have outdone this feat, recording the highest ever production volume.

The Galpaditenne Factory Has Over The Past 17 Consecutive Years Achieved The Highest Production Volume Not Only In Sri Lanka But Asia As Well…This Year They Have Outdone This Feat, Recording The Highest Ever.

“Big companies like Akbar Brothers, Jafferjee Brothers, Stassen and Lipton…they are very interested in buying our teas,” which he credits to the company’s “consistency, and the systems we have always applied to our manufacturing.”

At the factory the various automated processes run simultaneously, where the leaves from the troughs are subjected to rolling, fermenting, drying and grading, and with sophisticated colour sorters that are sensitive to the variations in colour, the tea input is sorted far more accurately than the older more traditional machines. The modern machinery is ISO 22000, HACCP certified, a testament to the high quality of the tea by international standards.

In regards to how a company can best weather the turbulence of changing markets, Saman is quick to suggest reducing liabilities: “If you don’t have too many liabilities, your mindset is strong in carrying out a business. That is a key factor of our group.” Constantly looking to improve upon quality and efficiency, they altered operations to include boilers that not only maintain a consistent temperature for tea drying but also impart a superior quality to the final product. When the size of the operation increased, they found great returns from automation instead of having to bus workers in from ever-growing distances. In the face of growing electricity costs, the KDU group instead diversified, and built the KDU Mini-Hydro power plant in Pelmadulla, which not only satisfies their manufacturing power needs but even contributes 1.4 Megawatts to the national grid.

For the KDU group, diversification is the name of the game. Although typically an Orthodox Tea operation, when the CTC (“Crush, Tear, Curl” – the alternative method for manufacturing black tea) markets in Kenya faced both oppressive weather conditions and increasing demand, KDU converted a part of Galapaditenna’s operations to CTC. Additionally the Group oversees a few restaurants including the popular pitstop Silver Ray and modern filling stations in Ratnapura as well.

Although about 90 percent of the Group is related to the tea industry, it’s looking towards many other industries in the future. “Tourism will boom very soon, and accordingly we thought of moving to the hospitality industry,” he says, simply.

With conscientiousness in every facet of the operation, the Group is constantly seeking to improve upon every aspect and their future in the tea industry. Accordingly he says, “my vision for the future is to gradually develop our own brand and establish a market for it.”