Fifty years back how did UTE mainly to operate the Caterpillar start out?

The company was formed in 1947 by my grandfather Granville Fernando together with some other directors involved in United Motors. They had this information that Independence was imminent and that there would obviously be some fairly massive development projects. My grandfather had the foresight to negotiate for the Caterpillar agency. Very soon after that with Independence in 1948, the Gal Oya development project got underway. UTE together with Caterpillar supplied a lot of equipment for that project.

What were the main lines of Business?.

Actually, the company started mainly to operate the Catapillar franchise. It was from there that subsequently other agencies were negotiated. Right now we handle over fifty- five different agencies. What has happened is that over the fifty years we decided that the market was not so good for some of these agencies that we had and dropped them. We took on new agencies. Like that we have remained fairly dynamic in catering to the needs of the market.

Right throughout the target has been the industries?

What we have now come to is to concentrate on industry as our market. We actually try to avoid getting into the consumer market. There were situations where we were selling two-wheel tractors and out-board motor engines. But we found that for the after-sales service required we have to have a very good sub-dealer network island wide. And we didn’t have that type of an infrastructure. So eventually we found out that what we were best at doing was approaching the industrialists direct.

How has the company performance been?

Over the last fifty years overall, the growth of UTE has been very much up and down. A lot has depended on governments’ policy for development in the country. During the 71-77 period, actually, UTE could not operate the Caterpillar franchise because the Tractor Corporation came in and took over all imports of tractors. During that period the company had to depend a lot on other areas of business. One of the areas that we were fairly successful was in selling locomotives to the Railway.

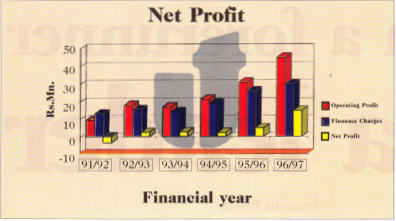

The last five years have seen a steady growth mainly due to the fact that now we are fairly well organised in our business units that we concentrate on. As a result, one year one part of the business might not be so good but then that is supported by another area of the business. In fact last year with the power crisis our power systems division has become the main money spinner.

After the last big hydropower project the Samanaleweva dam project, UTE had to go through a restructuring process, where we downsized and changed our business strategy. We became focussed towards our strategic business units. We formed the power systems division, environmental engineering division and we also had a civil engineering division. And then we had the construction machinery division. Using a more focussed strategy we were able to gradually build up our turnover. This one project (Samanaleweva) increased our turnover way beyond normal levels. Our overheads also increased.

When the project was over we suddenly found ourselves with a big gap. At one stage we used to depend on a few customers. Now in fact we have sort of spread out. As a result our own resources now are a little low in catering to so many new customers. We’ve had to incur a lot of expenses in cleaning up and investing in technology. Most of our principals are insisting that we invest in all this technology because it makes it easier for them to handle various training programmes. It is not a question of expanding the work force. It is a question of retraining them for this new technology.

In what direction are new synergies channelled?

Right now, what we feel is that we have to actually build up our product support capabilities. Most of our money is being reinvested into building up our workshops, adding more space to our workshops. Our main workshop is at Wattala. In 1990, we put the new workshop there. Then one and a half years ago we put up the warehouse and office space. Most of our heavy machinery division operations are at Wattala. Industrial products which really cater to hydraulic tools, building equipment… which are smaller industrial equipment, for that we have a separate set of operations from Union Place.

Our main investment is going into building product support capabilities to cater to the needs of our customers. There are more and more customers who want us to carry out regular servicing. At one time there were customers who were prepared to do their own repairs and services. Now what has happened is that these customers don’t want to be carrying the overheads of their own. workshops, tooling and mechanics. They now tend to come to us to provide them with the servicing. To meet that kind of a demand actually we are building up our capabilities.

On the generator side what we have found is that more and more people who had bought generators during the crisis, they haven’t thought about sound pollution. Once the generator starts running then only the complaints start coming. To solve that problem we have built up capabilities in doing some fairly effective sound proofing.

As indicated by UTE’s finacial results, 1996 was a bumper year ironically due to the power crisis. What were the results achieved by your power division?

In terms of number of units, Caterpillar units alone we sold something like 250 units. They range from 250KVA (Kilo Volt Ampere) upto 1875KVA per unit. In addition to that we also sold generators manufactured by a company called FG Willson. There it was a smaller unit from 27KVA upto 200KVA.

What were the units most in demand?

The most popular models last year were between 250KVA and 650KVA. For smaller industries we got the 100KVA which too was at very popular unit.

CEB is promoting the concept of ‘generating own power’. Are people seriously considering this option or are generators taken to be just stop-gap solutions?

You get both types. In fact, what we have done is we have invested in our own rental fleet for those who don’t have capital for a generator. We have right now about 14 fairly big generators from 650KVA down to 100KVA which we give out on rent. We are in a position to set up a unit and plug into the system within two hours.

Is this catching up?

It is a concept that is catching on. Here, in Sri Lanka, lots of people have this thing of if they pay for something they want to own it. It’s like land they want to own the land rather than use the land for what its worth. Generators are there to supply power. So you pay for the power only. You don’t bother about the owning cost. You leave that to the owner of the machine.

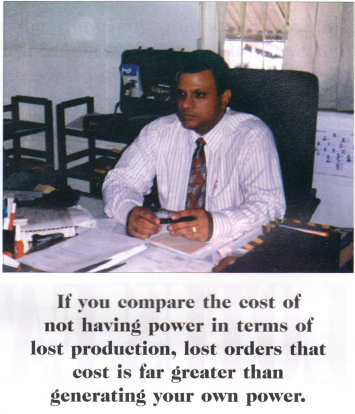

Do companies really benefit from generators?

The main benefit of having your own generator is that you have non-stop production. The power that comes off the national grid is definitely cheaper. But if you compare the cost of not having power in terms of lost production, lost orders that cost is far greater than generating your own power.

The CEB has now in fact given a lot of incentives to big industries to not rely on their power. One of the incentives stipulates that during the period January-June you have to actually get off the national grid. For that the CEB has subsidised the cost of generators. In addition to that they give a rebate to every unit of electricity that is produced using generator power.

How does UTE plan to mark its Golden Jubilee Year?

We’ve organised a series of events. One event was the launch of the new Scania truck. In April we are hoping to roll out the first rehabilitated locomotive. The 40 locomotives supplied in the 69-78 period are now being completely rehabilitated. We donated some equipment to the Army Hospital which they considered vital for their operating theatre and intensive care unit. We’ve also planned the launch of a new series of Caterpillar loaders. There are also several technology seminars we are planning for people who use generator power to highlight the more modern aspects of all these engines. Then we are also planning on having a competition for new apprentices in collaboration with the Institute for Construction Training and Development. They are opening a new training centre for heavy machinery mechanics. Together with them we are going to sponsor ten mechanics. There are a couple of other events also.

How do you look at the future?

A lot depends on how quickly the government can implement these various projects that are actually planned and ready for implementation. A lot of these projects have started moving. It has been a vigorous struggle for people like us who depend a lot on infrastructure projects to get going. The construction industry itself has been very slow. But all indications are that in the coming two- three years lots of projects will be implemented. This will in turn boost the economy.