by Ajita Kadirgamar

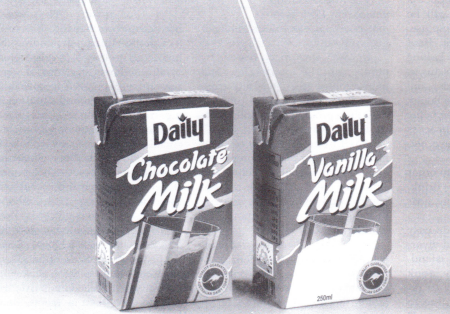

Lanka Dairies (Pvt) Limited (LDL) is a subsidiary of the Stassen Group which now counts 22 companies. LDL is currently in the news with the launch of its first product ‘Daily’ Ultra Heat Treated (UHT) vanilla and chocolate flavoured milk cartons with a shelf life of six months.

LDL, formed in 1994, is a Rs. 300 million venture, the first BOI approved dairy development project in the country.

DAILY carries the Australian Dairy Corporation (ADC) logo which is a mark of international quality. A resident Australian expert supervises production in Sri Lanka, enabling the milk cartons to carry the tag “packed under supervision of AUSDAIRY” (the marketing arm of ADC).

As far as packaging goes, LDL has tied up with Tetra Pak of Sweden, noted to be one of the best packaging companies in the world.

What prompted Stassen, already such a diversified group, to venture into dairy products?

According to Stassen’s Chairman VP Vittachi, “depending on imported milk powder we are at the mercy of the world market and its price fluctuations”. He feels, we must provide employment in this country and also initiate the growth of the local dairy industry.

Ranjith Attygalle, the articulate and motivated Finance Director of Lanka Dairies Limited elaborating further on the company’s mission says, “Stassen felt it was time to do something for the nation. It is obvious now that the country needs dairy development. A lot of money goes out on importing milk powder. and this cannot go on forever. With whatever limitations we have, Sri Lanka must one day go in for local dairy development.”

The production of milk cannot be increased overnight as Attygalle points out, but someone has to make a start and to this end LDL has stepped in.

“…It is obvious now that the country needs dairy development. A lot of money goes out on importing milk powder and this cannot go on forever. With whatever limitations we have, Sri Lanka must one day go in for local dairy development…”

Says Attygalle, “our strategic plan is to go into 100% development of the dairy industry and to be the leader in the milk industry in the country.”

At present, LDL collects milk from the Gampaha district. (Dompe, Pugoda, Kapugoda, Malwana, Kalukondiyawa, Hanwella) and the Kurunegela district (Kotawera, Mahananeriya, Anamaduwa, Galgamuwa).

LDL provides the farmers of these areas with some necessary infrastructure such as veterinary services and cattle feed, and they collect the milk in an organised way paying the highest price to the farmers.

“We are fully aware of the toil the farmer has to go through to give us this milk. So we pay the correct price at the correct time. We also give them loans and whatever they require for dairy development”, Attygalle says.

“We have given each farmer a 10 litre can, otherwise they tend to bring milk in the bottle they bought kerosene oil the previous day! We are trying to improve their hygienic conditions which are in a terrible state right now”, he adds.

LDL does however own a farm situated in one of the companies’ tea estates in Haldamulla in the Haputale district.

Here large cattle sheds have been constructed to house the animals and new stock has been bought from the National Livestock Development Board. A veterinary surgeon and experts in artificial insemination are on hand and the diary is run in a methodical way. Automatic milking machines have been ordered and this site will eventually be a model farm.

There is an interesting connection between Stassen’s dairy. and its lucrative tea industry which provides. the company’s main export product-one feeds the other as it were.

Stassens produce what is known as “Bio Tea’, an environmentally-friendly tea, grown without the use of pesticides and artificial fertiliser, catering to an ever growing market of natural food lovers.

As Chairman Vittachi points out, “we are the pioneers of Bio Tea in Sri Lanka and it fetches very good prices in sophisticated markets like Japan and Germany. We use the cattle manure from the dairy cows as fertiliser so it serves a double purpose. Is it possible then that liquid milk may someday overtake powdered milk in popularity, convenience and price thereby paving the way for a war with milk powder, which is one of Stassens import products?

Attygalle’s response is that even if Sri Lanka improves its dairy production to 100% there are still limitations such as available grazing land and climatic conditions in the country. So production of liquid milk will still be limited and imported milk powder will always have its place.

There are already several imported brands of UHT milk available in Sri Lanka. However Daily has instantly proved to be extremely popular and for within a week of hitting the fast moving market, the company was finding it hard to keep up with the demand.

At Rs 15/- per 250 ml. carton, it has found a niche market especially with children, and price wise it is at least fifteen rupees cheaper than any imported brand in the market.

LDL also plans to introduce a litre carton soon which will be more convenenient for home use.

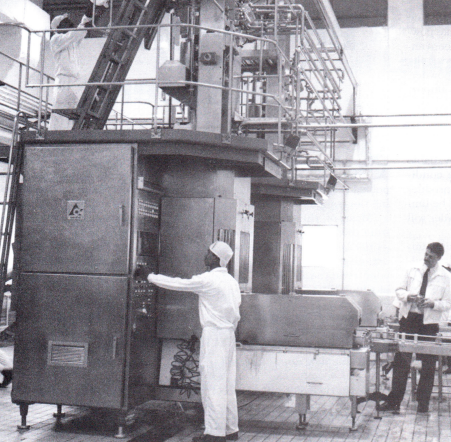

The process of Ultra Heat Treatment (UHT) involves boiling the milk to 140 degrees celsius in a matter of three seconds, and then immediatly cooling the liquid, which results in all bacteria being killed off. However, this process does not affect the nutritive element of the milk.

LDL plans to launch into other allied milk products such as drinking yoghurt and curd in the near future.

Marketing Daily is made easy by Stassen’s intensified and diversified marketing network, island- wide. This enables every nook and corner of the country to receive the product, according to Vittachi.