The footwear manufacturing industry has the potential to become the second largest industry in the country next to garments, if the programme outlined by the Footwear Association is implemented, said the newly appointed president of the Footwear Association of Sri Lanka, K L Chandralal de Silva, who is also the Chairman and Managing Director of the Bettans Group of Companies. In an interview with Sassanka Samarakkody of “Business Today” he spoke about the state of the country’s footwear industry and what needs to be done to improve standards.

The local footwear industry has vast potential and the introduction of modern technology is vitally important to improve the quality of the product. The newly appointed president of the Footwear Association of Sri Lanka, K L Chandralal de Silva, said: “We cannot produce a high quality product here because there are no proper facilities for shoe manufacturers in Sri Lanka. Therefore, we have drawn up a programme to uplift the overall standard of the footwear industry in the country. “The footwear industry could become the second largest industry next to the garment industry if the programme we have outlined is implemented,” he added.

Even a single person can manufacture footwear at home, as a cottage industry, according to De Silva. In fact this is how he started his very successful business – Bettans Group of Companies.This self-made entrepreneur started making ladies’ shoes in 1983, in a 150 sq ft rented room with a capital of Rs25,000 given to him by his wife. “It was my wife who gave me the idea. Her brother is the owner of GiGi Shoes,” de Silva recalled. “At this time I did not know anything about making shoes. My wife copied all the designs from her brother’s workshop, into a CR book. I am a fast learner and very soon I was making shoes and personally marketing them in places like Kandy and Galle.”

His elder brother, KL Lakshman, nurtured De Silva’s cottage industry with a further capital infusion of Rs. 50,000 from his personal savings, which enabled him to move to another rented workshop in Maradana.

De Silva said: “I now had about 20 people working for me. Then came the 1983 riots and that created a setback. But I never gave up; I persevered. I used to supply shoes to Bata and when I visited its factory I was inspired to start something like that on my own. “I must mention that my brothers and sisters rallied round me to help set-up my operation and later, they themselves started their own footwear manufacturing units on a small scale, which they operate to date. I will fail in my duty if I also do not mention the unstinted support rendered by my colleagues at the University.

“With the opening of the economy, sheet rubber soles were made in Sri Lanka by local manufacturers. I managed to get a mould set made, which helped to increase my production capacity. I still did not have my own brand name. What I did was, copy the designs of imported shoes, especially from Thailand. These were selling very well in places like Kandy, Galle and Kurunegala.

“Since my business was expandin° I shifted to Peliyagoda and managed to obtain a loan of Rs825,000 from DFCC bank and another loan from Sampath Bank for Rs400,000, which I invested in purchasing machinery. Then the 1989 uprising happened, where there was a lot of unrest in the country. But that too did not discourage me, I was determined to establish my business and make it a success. I also managed to settle the bank loans.”

In 1990 De Silva established his own factory on a one-acre plot of land in Kelaniya, which he purchased through another loan obtained from Sampath Bank, which had then started a special loan scheme for small and medium-scale entrepreneur (SME). “Aravinda Perera of Sampath Bank, who pioneered the launch of SME Loan chemes in Sri Lanka, was instrumental in organizing the funds to bu the land. I then purchased the required machinery, one by one,” he said.

Then a question of obtaining leather arose as it was costly to purchase fr9m outside. “I decided to purchase the leather in its raw form and get it finished at a tannery, owned by one Mr Pathmanathan. He later left the country and I rented out his tannery and ultimately bought it from him.

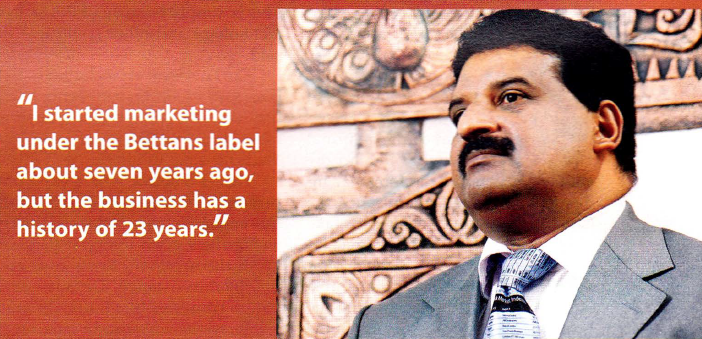

At that time I did not have any knowledge about leather manufacturing. But I employed people to produce the type of leather I wanted and Sampath Bank again gave me a loan to purchase the machines for the tannery. I thus managed to manufacture all the leather I wanted, which I did not sell outside, but manufactured shoes for the wholesale market. “I started marketing under the Bettans label about seven years ago, but the business has a history of 23 years.”

In 1993 he attended an international fair in Germany, for the first time, sponsored by the Export Development Board (EDB) and was expo ed to the international market. “I managed to secure some small orders to Moscow, Chilli and Belgrade. MP T Cooray, the present CEO of Lanka Putra Development Bank, who represented the BOI (Board of Investment of Sri Lanka) in the capacity of deputy director general and whom I met at the Moscow Trade Fair, was impressed with the ‘Bettans’ products on display. hen he return to Sri Lanka, he extended BOI facilities for me to enter the export market. Initially I had to struggle as the local industry was not geared to meet such high standards.” He explained: “The footwear industry in Sri Lanka has been stagnating for the past 20 odd years without any improvement, resulting in the local market been flooded with imported shoes, which is a blow to the local manufacturers.

“Although the government imposed a special levy on imported shoes it has had no impact at all. There is also a lot of smuggling going on.” In order to up-lift the industry and to introduce modern technology, the Footwear Association has decided to embark on an ambitious programme to promote 10,000 small scale footwear manufacturing units throughout the island. “We will be supplying small-scale entrepreneurs with the required equipment at an affordable price. At the same time, we are planning to open 50 mega factories in a special zone, where the material required for the industry will be manufactured and provided to them. We have already found a 60-acre plot of land, which the government has agreed to lease out to us on a 99-year lease. This will be an exclusive zone where only footwear-related material would be produced.

“When we attend international fairs we realise how far behind the country is as far as the footwear industry is concerned. For instance, the Chinese who attend such events take photographs of the new designs, instantly send them back to their country, and before they leave the sample is in their hands to be shown to the buyers. This is simply because of the introduction of modern technology into the manufacturing process. We should set up CAD CAM centres, like in other countries, in order to reproduce designs quickly. “In Europe the designs and colours, etc., change every three months and it takes some time for these to reach us. But due to the advanced stage of their industry, countries such as China, India and Taiwan have the capability to copy the new designs and market them quickly.

“Here, we lack the infrastructure, for example, to make moulds according to international standards. So we have to get them done in India or China. Then the availability of raw material is another issue. Due to these reasons, it takes about one month for a local manufacturer to make a copy and put it to the market. This is simply because of the lack of technology and other facilities,” he said.

The Footwear Association is also planning to set up a training institute, with the support of the Government, and the Ministry of Small and Medium scale Industries.

This is a sector where even one person or the members of one family can engage in as a cottage industry and make a good living, if they are given the necessary know-how and financial assistance. De Silva said that in countries like India, decorating footwear with beads, lace, etc is undertaken as a cottage industry. “We are surrounded by the sea, and can easily make use of our sea shells as decorative effects, as well as wooden beads, lace, etc. Because, in the international market they like the natural effect.”

Another issue that has an adverse effect on the industry is a scarcity of raw hide, to produce quality pure leather footwear, which has a huge overseas market. The supply of hide should be steady, said De Silva, for the manufacturers to confidently obtain overseas orders.

“We can compete with the international product, if we get the required support from the state as well as the co-operation of the industry as a whole. We have to work together. That is the only way forward.” De Silva added: “President Mahinda Rajapaksa and the EDB is willing to assist us in our endeavour.” As far as the future plans of the Bettans Group is concerned, they want to work collectively with other manufacturers to uplift the standard of the local footwear industry.

“In the future we hope to penetrate the international market, and will be focusing on manufacturing up-market high quality footwear for that segment as well as mass produce for the lower end of the market,” said De Silva, looking towards bright prospects for footwear made in Sri Lanka.