What would life be without printed matter? Very few people stop to think that life without books, newspapers, periodicals and even the common carton or box used in packages, would be dull and boring; not to mention leaving us totally in the dark about what’s happening.

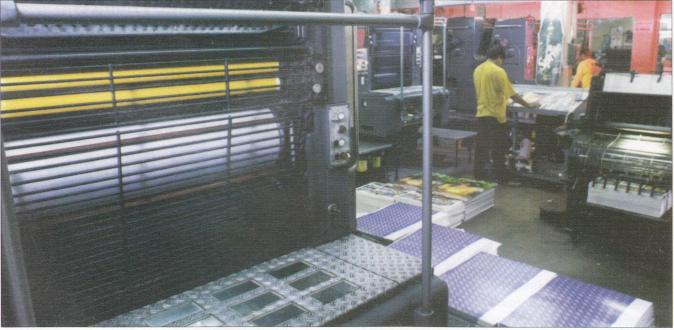

The printing industry, is believed to have been brought to Sri Lanka by the Dutch, and today Sri Lanka has nearly 2.000 printers to many small timers who run a printing press from a shed in their garden. Development in the industry in the last 25 years has been very rapid and had actually taken off with a bang when the open economy policy took “Technologywise, we are completely up to date”, says Sanjeeva Fernando. Director of J K Packaging (Pvt) Limited (a subsidiary of the John Keells Group). “The printers have all the facilities available with up to date equipment. Quality and service, in comparison to European countries, are very competitive”. Mortlake Press is over 100 years old and subsequently became the support arm for the inhouse printing of the Group. Asoka Gunaratne, Chairman of Gunaratne Offset which is specialising in commercial printing, especially the printing of books,

however felt that even though quality is competitive in the local market, with regard to foreign markets, Sri Lanka still has some way to go. According to Gunaratne. Sri Lankan printers face problems when it comes to delivery dates. “Foreign buyers want deliveries in double quick time. We sometimes don’t have the equipment to meet the demand. For example, if our capacity is 500 to 1000 books per day, our buyer wants 100,000 copies in two weeks’ time. We cannot invest in state-of-the-art equipment to meet a demand of this sort because of the amount of capital involved and moreover, because we are not assured of a confirmed order of this nature continuously.”

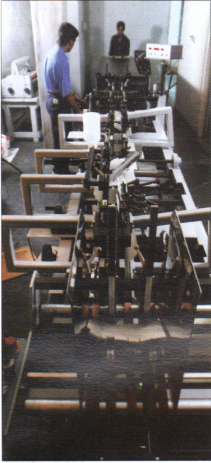

Ranjith Gunaratne, President of the Sri Lanka Association of Printers and Managing Director of Gunaratne Offset, says that most printing companies have in the last five years invested in new equipment. “With the Government’s decision to encourage tea exports as value added tea, printers have taken up additional capacity, which is a good sign. Most of the printers survive now on printing of cartons, box board, packaging, and tea bag tags this is an area that has to be improved in volume” The Association of Printers with a membership of about 300, carries out regular seminars, workshops, an annual exhibition and awards for printers, to gain the necessary knowledge in an ever-changing technology and also to give them a chance to look at their competitors.

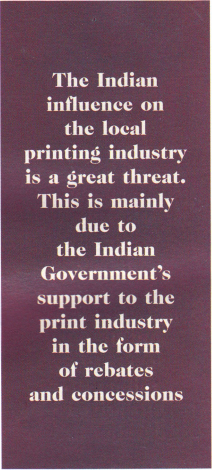

The Indian influence on the local printing industry is a great threat. This is mainly due to the Indian Government’s support to the print industry in the form of rebates and concessions and also due to the fact that India has a very developed paper industry. “Last year the problem was very bad”, laments Fernando. “mainly because indirect exporters (like tea exporters) ordered their packaging from India. The Indian price was 65% of our prices and we just don’t have a chance of matching those prices even if we get our materials on a duty- free basis”. India has the advantage of producing her own raw materials and ancillary products and India being the giant that she is, will capture the entire export printing market, unless schemes are brought about to redress the problems of our local printers. Says Fernando, “some Indian printers don’t even keep a markup – they survive on the rebate given by the Government.

The Indian takeover is affecting not only the big time printers, but even the small and medium ones Priyanga Perera, Managing Director of Sky Paramount (Pet) Limited, specialising in printing for export and In the printing and packing of sachets says that about 6 years ago, South East Asian countries were far behind us including India. “But what has happened now? We are buying paper from countries like India, Indonesia and Malaysia and the paper quality is far superior to that produced here. The Paper Corporation must play a bigger role in the country.

It seems a waste that we have the assets for paper manufacture, but no one seems to be taking the initiative to develop it. I feel that if there are individual investors who would like to invest in the development of this area, they should be given all the concessions possible, so that we can start servicing the local paper and printing industry without having to rely on imports all the time: We will then be competitive, at least in this region”. These sentiments were echoed by Ranjith Gunaratne, “India’s large paper manufacturing concern has been given a helping hand. all the way by the Government. The Printers Association here has been succesful in getting the import duty reduced on most paper items but in the long term interest. I feel that our Government too must give further encouragement in this area thereby assisting our local printers. This will be very helpful to them when it comes to the export sector.

However, the reduction of duty and incentives given to the industry

does seem to have its pitfalls. “Although on paper the Government has reduced import duty in various areas, there are hidden taxes that amount to almost 50%”, says Dr. Neville Fernando, Chairman and Managing Director of J F & I Printers. “For instance, we have to pay BTT and the Defence Levy. Then there is BTT that is added to the profit and I think that there is a different interpretation altogether by the Treasury as opposed to what the Government says. Duty must be calculated in a stipulated manner so that the concession goes down to the importer”. About 75% of the raw material needed for the printing industry has to be imported, especially the paper. Printing ink, for run-of-the-mill jobs, can be obtained in the local market but good quality ink is generally imported. “Imports before a certain date can be written off against the profit. But again, the paperwork etc., must be started at least months before the shipment arrives and even then, if the shipment arrives 3-4 days late, we are faced with a stumbling block. Nothing is stipulated and interpretation depends on the individual department or ministry.”

Looking at the other side of the coin, there are a large number of printed books that are brought duty-free into the country, whereas, the local printer who prints books pays duty on the paper as well as on the ink and other raw materials used. Further, his overheads are high with the taxes he has to pay and probably due to the credit obtained for the imported machinery. According to Asoka Gunaratne, “Singapore pays only 3% on loans for machinery but we pay about 24 to 26% on our loans plus the BTT, Defence levy. Commission agents etc. Unless we get some sort of incentive, printing is just not feasible any more.

With these problems come the fight for survival and the undercutting that goes on just to get one job. “Printing has become a dirty business. There is no unity among the printers at all. The undercutting that goes on where even big printers pose problems for the smaller ones, has become really bad”, says Privanga Perera. However, the thought behind this is, that each day that a machine is kept idle costs money, hence, it is better to have at least one low paying job than none at all and at the end of the day, the consumer gets the benefit of the better price.

The future of the printing industry hangs in the balance. There is a dearth of good personnel and profit-making jobs. Advancing technology is leaving us behind. To combat the problem of lack of good personnel the Association of Printers has begun an awareness campaign in schools to encourage students to consider printing as a career option, with funding from SMED (Small and Medium Enterprise Development Project). A Durch funding agener is having preliminary talks with the Association. the Export Development Board to start Printing School which will be operational in the next 12 months. However, there is much more to be done. which probably cannot be done over-night.

Sri Lankans, as a nation, are a very persevering lot always aiming to get to the summit, no matter how difficult. The printers, given the present situation. feel that the only way they can he come leaders in the industry is by being given exposure to foreign markets, with 4 helping hand by the Government to become more competitive and quality conscious. With the investment drive in focus, this might be a good time to think of the industry not only as a support arm for exports, but also as a lucrative export in itself, in future.