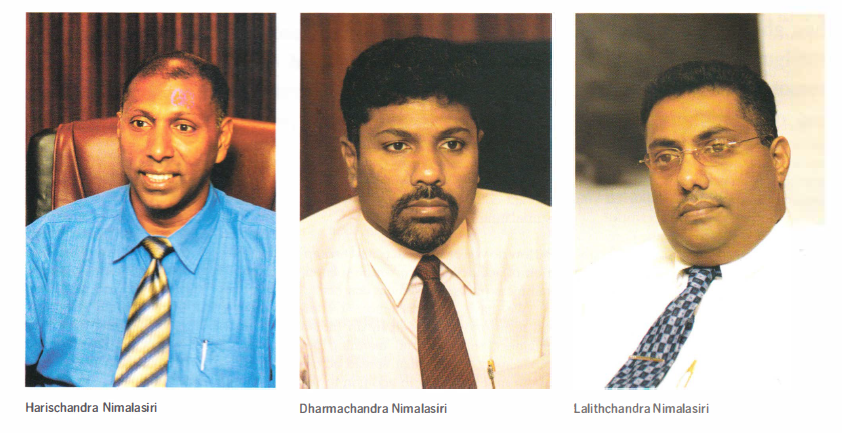

P G Martin, one of Sri Lanka’s foremost homegrown companies, celebrates 50 years in business in 2005. Today the business is spearheaded by the second generation. The Nimalasiri brothers – Harischandra, Dharmachandra and Lalithchandra – have added diversity and vitality to the charismatic P G Martin brand name.

Harischandra Nimalasiri, the eldest, ventured into the children’s entertainment sector with P G Martin Wonderworld Entertainment. Dharmachandra Nimalasiri commenced the manufacturing arm of the business with P G Martin Industries, and the import and trading of luggage falls within the purview of Lalithchandra Nimalasiri.

In this interview with Business Today, the three brothers speak about the company begun by their late father.

By lshani Kuruppu

How did the P G Martin shop start operations back in the early 1940s?

The founder of this company, our father the late P G Martin Nimalasiri, started from rock bottom. Hailing from the south, he came to Colombo in search of a job and with no money. He first sold pineapple by the roadside and later joined the harbor” as a laborer but due to a strike, was made redundant. He then opted to help his brother’s business of selling ceramics on the pavement. This gave him the initial feel of business. Eventually he decided to start a business of his own. This was during World War II when there were a lot of imported shoes in the market. He started his business by selling 10-12 pairs of shoes along the First Cross Street pavement. After some time in 1948, he registered his business and established a small shop in First Cross Street. He remained at this location until about 1965. With the business picking up, he ventured into manufacturing, which was supervised by our mother. In 1971, they expanded the business by opening a second shop on Galle Road. Since our mother was now busy overseeing the operations of the second shop, they gave up the manufacturing aspect and turned to sub-contractors for their supplies. In 1971, with the opening of the second outlet, our father succeeded in obtaining the sole agency for Ceylon Leather Products. This was the turning point in the business. From this point onwards, with the help of mass advertising, the name P G Martin became popular. During the early 70s, unlike now, most people from all over Sri Lanka would come to Colombo for their purchasing. For them, P G Martin was the one-stop-shop for their leather and footwear needs.

Dharmachandra Nimalasiri, as the first to enter the family business, can you detail how you and your brothers entered the company?

In 1983, I went to the UK for higher studies as my father was keen that I completed my education before entering the family business. I completed my Diploma in Footwear and Leather Goods Technology and returned to the island in 1985 at which point I joined the family business. My elder brother who is qualified as an Electrical Engineer was working at British Rail in the UK at this time. In 1987 my younger brother joined the business. As I was involved in manufacturing, he decided to get into imports. When my elder brother returned to Sri Lanka, he ventured into children’s entertainment under the P G Martin brand.

How did P G Martin move into the import and trading of luggage, having established a business in the footwear industry?

With the opening of the economy in 1977 many people started traveling overseas. At this time, the footwear market was also becoming competitive with a marked increase in footwear available locally. In addition, the changes that took place at the government-owned Ceylon Leather Products Corporation prompted our father to look at alternative ventures. In 1977 he gradually entered the import and trading of luggage. Today we have six luggage outlets employing a staff base of almost 60 people.

How has the luggage business responded to the changing needs of customers?

We have been concentrating on imports of reputable brands from China like Diplomat and President. Simultaneously we sell our locally produced luggage carrying the trusted P G Martin label. About five years ago we starred importing global brands such as Samsonite and American Tourister. Recently, Samsonite tied up with an Indian collaboration to set up a manufacturing facility in India, thus making India the hub from which the entire Southeast Asian market is serviced. The Samsonite products available here are imported from Belgium and India. The molded fiber luggage is manufactured in India, whereas the soft luggage is manufactured in Belgium and other countries. Even the products manufactured in Belgium are sourced through India, which is the central distribution point for Southeast Asia.

Samsonite is a global high-end brand of luggage. What ha been the customer response for such a premium brand in terms of price competitiveness?

Yes, initially we had reservation” that there may not be a market due to the high price. However. we have now realized that price is not an issue. There is a significant niche marker in Sri Lanka with the purchasing capacity to pay a higher price for a premium product and brand. Another aspect is that Samsonite products sold through our outlets are very competitive compared to the prices in Europe. Our prices are 30-40% less than the European prices. So this is an added impetus, even for tourists who visit here to purchase Samsonite products at a good price.

How has the partnership with a global brand such as Samsonite helped you in your business in Sri Lanka?

The alliance with Samsonite has proved fruitful in many ways. We have learned a lot from our Indian principles. For instance we located two P G Martin luggage shops in close proximity to each other on Havelock Road – one is the exclusive Samsonite Showroom and the other is the P G Martin Luggage Collection housing all the brands except Samsonite. We have found that such a segregation of premium and mass brands is an effective branding and marketing strategy. Joining hands with Samsonite has given us, a competitive edge. Frankly, it has given much strength and mileage to the company.

What are the additional service that you provide for your customer in the luggage sector?

For the last 25-30 years, we have been providing a repair and replacement service for all leading airlines. Luggage that is damaged in the process of forwarding by the airlines are repaired and replaced as deemed fir through this service. We repair almost 75% of the luggage forwarded to us and replace only if it is really necessary.

Can you explain the nature of the P G Martin manufacturing operations?

We re-initiated the manufacturing arm in 1985. I am proud to say that a majority of the genuine leather orders in the corporate market are handled by us. We undertake orders for private sector companies. airlines and leading hotels and even many of the ministries and government departments. Our range of locally manufactured, personalized leather items includes leather bags, file folders, wailers, pouches and even leather furniture. Our factory in Homagama has a daily capacity to manufacture approximately 200 leather bags and 1.000 soft luggage items. In our quest to be competitive in the marker we have concentrated on manufacturing mainly genuine leather products. We have contracted manufacturing of luggage using other materials such as Rexine. We have about five subcontractors working with us. All our products carry the P G Martin brand name. Our manufacturing operation directly employs about 45 while another 150 workers are involved indirectly.

What is the market share you have captured in the local luggage business?

We dominate a 75% market share of the luggage business in Sri Lanka.

Harischandra Nimalasiri, you have pioneered the children’s entertainment industry in Sri Lanka by being the first to introduce indoor and outdoor amusement parks. What spurred you to form PG Martin Wonderworld?

I realized the void in the country’s children’s leisure and amusement industry. I noticed that the market was flooded predominantly with substandard kiddies’ items. High quality branded play equipment and baby products were non-existent at that time. We began by introducing play equipment such as bouncing castles. In 1995 we started Sri Lanka’s first indoor adventure park in Majestic City. Riding on this success, we expanded into two other shopping malls – Liberty Plaza and Crescat Boulevard. In 1995, we introduced exclusive kiddies’ products through our outlet in Majestic City. These items are now marketed through our entertainment centers. We also have the exclusive kids gift shop on Havelock Road. Here too our experience is that a majority of the customers seek quality and are brand conscious, and thus prepared to pay a premium price. In 1999, we started the first outdoor amusement park at Millennium Park (now known as Excel World).

What are the children’s play equipment and gift items you specialize in?

We are the sole agent for Little Tikes, a leading US brand of children’s toys. We also stock well-known brands of baby care items and toys like Mothercare. The branded products are expensive as they come from the UK and USA, hence the quality is guaranteed. All of our play equipment is plastic and complies with strict international safety standards, minimizing accidents and are thus wholeheartedly endorsed by parents.

What are the other services P G Martin Wonderland extends to its customers?

We have introduced a parry hire scheme whereby kids· play equipment such as bouncing castles and toy rides are hired for special events such as birthday parties and corporate Christmas parties. Our mobile units deliver and install the play equipment at the respective locations. Our services have been extended to leading hotels in and our of Colombo. The play equipment provides recreation for the children who find the vibrant colors mentally and physically stimulating.

How do you ensure safety and prevention of accidents when running entertainment parks/amusement centers?

We have a considerable technical team of 100, headed by an Indian engineer, servicing and manning our amusement centers that spread across about nine locations in addition to the three outdoor parks. The maintenance and safety of the equipment are of paramount importance to us. Additionally, most of the equipment is sourced from the US, UK and Italy so we have the support of the overseas supplier base. The daily maintenance checks comprise a comprehensive array of functional and maintenance rests which are carried out on each and every ride. People think it is easy but this is serious business. Any complaint made by a customer is taken very seriously and any fault is rectified.

With the proposed relocation of tanneries to Bata Atha in Ambalantota there has been a shortage of raw leather in the market. This has compelled local manufacturers to import raw leather. Has this move affected your business?

Yes, the local tanneries had to relocate as there was an environmental hazard created by the discharge of effluents. As a solution, an area in Bata Atha in the Ambalantota district has been designated for relocation of the tanneries. A common effluent treatment plant for the tanneries has been built, which was funded by NORAD under the expertise of the UNIDO. As a result of the relocation. there was a shortage of raw leather in the market. We had to lobby the government for a period of two years to grant the leather raw material imports on a zero duty basis. We were successful in obtaining a reduced import duty of 3% until the tanners completed their relocation. Despite this, most manufacturers haYe been hampered to increase production as it is still not cost effective to import the raw leather.

What are the impediments to the leather manufacturing sector in your experience?

One of the main problems we have in the leather manufacturing sector in Sri Lanka is the shortage of unskilled laborers. Although the government and almost everyone complain that there is high national unemployment, it is very difficult to find unskilled workers. Our demand is not being met by adequate supply. Instead of employing more people we have adopted an effective policy whereby we give our employees additional work, which they can do at home, and thereby enhance their remuneration.

“Our father has built up the business with the focus on the customer’s needs and expectations and we have been trained and educated in that manner. Throughout our SO-year-old business legacy we have consistently provided unrivalled customer service, which is the secret of our success in attracting repeat customers to our shops over the years.”

Is there a situation where unskilled labor is available but the unemployed is somewhat selective in choosing employment?

That’s right. I have spoken to a few ministers from the respective electorate but the response has been disheartening. I was under the impression such a request for employment generation would be met with a more positive response. There is evidently something wrong with the system.

Presently, the total footwear production in Sri Lanka is 30 million pairs per year, of which only 10% is made of genuine leather. What are your proposals to take the leather industry forward in Sri Lanka?

I strongly believe that our national education system should change. Presently there are metal and woodwork studies in certain school curriculums. Leather and footwear manufacturing training should also be introduced into the academic curriculum. This type of training would close the skills gaps in both design and production and would train youngsters in the basics of manufacturing thereby leading to future employment. In India, this sector is doing very well with leather and footwear as their leading exports. The BOI and Ministry of Industries have identified the leather and footwear industry as a priority sector. Especially with the termination of the apparel quota system in 2005. this is an ideal opportunity to develop this sector. With the growing global footwear market, there is further potential in this market. Although these facts have been highlighted during the last 3-4 years, no action has been taken. Two years ago, a committee and task force was appointed and in consultation with the IDB and Ministry of Industries, they put forward various proposals. However, these have not been implemented to elate. Unfortunately. when a new minister assumes office, previous proposals forwarded by the sector itself are not implemented. There is an urgent need for an integrated plan to develop this industry.

What expansion plan do you hope to implement this year with regards to the luggage and manufacturing business?

We hope to open our seventh luggage outlet in Colombo imcl a luggage collection showroom in Kandy soon. Plans are also underway to open a shop in the departure lounge at the Katunayake international airport. The range of international brands will be further increased with the launch of Ankler. a UK brand of luggage. On the manufacturing side we hope to commence exports to Pakistan. We intend to import luggage parts from China, assemble the pieces here and then export the finished goods to Pakistan.

What expansion ideas have been planned for the children’s entertainment sector?

We have already agreed to set up a spacious amusement center at the new shopping complex to be built in Kandy town, near the Dalada Maligawa. In Colombo too we are looking for a more sizeable location to start a new operation. We hope to be present in the suburbs as well so that people need not travel to Colombo every time. We envisage a demand for children’s entertainment with the improving of the tourism sector. There is potential for a lot of business activities but of course, all this should be supported by the government. For instance, we have been trying to set up a large-scale outdoor amusement park for the last four years. Such a venture entails heavy capital expenditure as the equipment is very expensive. We require the support of the government who can provide us with the land.

In your view what sort of infrastructure is conducive for a business such as yours?

One of our main concerns is the development of infrasrtucrure such as highways. For example. construction of the Colombo-Kandy highway has been dragging on for years. Even for this new shopping center in Kandy, if the road network was good. a lot of people would travel to Kandy from Colombo for their shopping. Politicians drag completion of projects for years. It is time to concentrate on the infrastructure. Even for tourism, improving road infrastructure is a primary requirement. We are used to traffic congestion. hut for tourists, ease of commuting is fundamentally important.

In our opinion. what kind of incentives should be in place for the manufacturing sector?

The government should support manufacturers by providing them with land. We have to purchase it even in the free trade zones. With the high cost of machinery and construction, investing in land as well is a practical problem. In the case of our land in Homagama, the government has given it on a lease scheme where we have to re-pay the cost in 10 instalments for which an interest is charged at 16%. For the last two years we have been fighting against this injustice. The government should set up investment parks and offer the land at concessionary rates as an incentive to manufacturers and entrepreneurs, taking into consideration their large investments and employment generation potential.

As a socially responsible company, what sort of community development work does PG Martin undertake?

Our organization has always been focused on community development and charity. After the recent tsunami disaster, we arranged a convoy of essential goods to be sent clown south. We plan to take our mobile entertainment units to the relief camps in order to provide the affected children with some form of joy and happiness in order to ease the mental trauma of this tragedy. We make frequent such visits to the local hospitals and orphanages free of charge to uplift the spirits of the children.

That would be the main guiding principle instilled by your father that you hope to emulate?

Our father has built up the business with the focus on the customer’s needs and expectations and we have been trained and educated in that manner. Throughout our 50-year-old business legacy we have consistently provided unrivalled customer service. which is the secret of our success to attracting repeat customers to our shops over the years.

We hope to preserve the customer-focused strategies in the future as well. We strongly believe that our main strength is our employees. So it will be an employer-employee partnership that will drive our company to greater heights of success.