Dilki Wijesuriya

Mobitel, the second cellular operator to venture into the Sri Lankan market has certainly not been second in the service it has provided to its customers. With an excellent network reaching most parts of the island, the company has decided to further enhance its ‘customer service’ by implementing a ‘Quality System’ which will enable them to meet the world’s best practice.

The concept of this system, whose implementation is the brainchild of Mobitel’s managing director Walter McKenzie, though new to Sri Lanka is not new around the world. Says McKenzie, ‘It is new to Sri Lanka but it is not a new concept around the world. What it actually is, is the development of a “quality approach towards servicing”. When it comes to quality we are looking at a commitment from management all the way down.”

When Walter McKenzie took over the management of the company 12 months ago, it had just been converted from a ‘build, own and transfer’ company to a joint venture with Sri Lanka Telecom. ‘It soon became obvious to me that if the company was to remain successful in spite of the then current alarming trend of falling sales, a major shift in the company’s culture and operations was necessary. What was needed was a culture that was customer-focused and marketing- oriented. So, as is done in most organizations, I got our senior managers together and we developed a mission statement and a set of values which would embody our new company culture. We then spent most of the next six months restructuring the company mainly in the areas of marketing, sales, distribution and customer care. Currently our human re- sources division is being restructured and refocused

on staff development, career management, change management, empowerment etc.,’ McKenzie said. Having set the basic building blocks in place, the company is now ready to develop a strategy to make

each of those areas ‘centers of excellence.’ Walter McKenzie who has gained wide knowledge and experience in the implementation of ‘Quality Management’ during his stint with ‘Telstra’ Australia, feels that this is the most appropriate framework to adopt as it embodies the concept of ‘continuous improvement,” one of Mobitel’s seven new values. He says, one of the benefits of a continuous improvement process is that it encourages a participatory process from staff involved in the process as they are often the best equipped to suggest and manage the improvement.

Says McKenzie “To me Quality management (QM) is a commitment, from all staff, from the CEO to the mailboy, to the process of continuous improvement. Improvement first and foremost from a customer service perspective and then from a resource effectiveness perspective.’ Mobitel’s Customer Care Section whose present staff strength numbers around 25 has been completely revamped with a back and front office operation to give their customers who call over or phone an uninterrupted service.

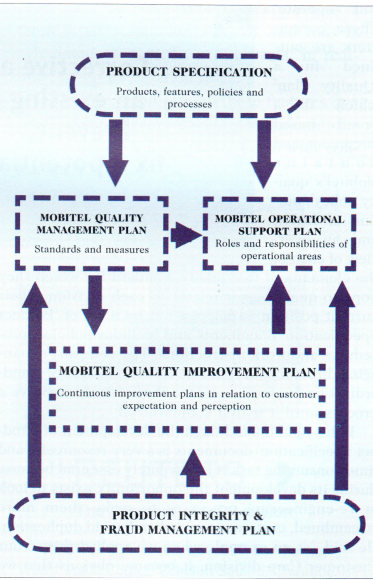

With the new system in place the company aspires to qualify for the ISO 9002 standard. But before they can set the plans for improvement in motion, the company’s management intends to clearly establish their current position and the framework within which they will operate. These parameters are outlined in a “Quality Plan’ which is a broad based document and contains Mobitel’s ‘quality policy’, outline of intent and an overview of each of Corrective actions fix an existing problem. Preventive actions fix a potential problem. the elements of the quality standard for which they hope to qualify, as it relates to each division. Their current position is mapped out by a set of ‘Product Specification’ documents and includes policies, procedures and work instructions. The company’s managing director said that this leads to a form of standardization because one cannot effectively improve a process until it is first standardized.

In his opinion, although the development of ‘Product Specification’ documents is a very resourceful and time consuming task it is absolutely essential because during its development the opportunity exists to look at re-engineering processes to make them more streamlined, customer-focused and avoid duplication. He said, ‘as an example when we applied this to our Customer Care division, it became obvious that we badly needed to re- structure the current processes into separate front and back room operations. We also were able to incorporate the benefits of multi-skilling for both our credit control and customer service staff. While most of our customers feel that we have the best Customer Care as compared to our competitors, I feel that we still have a lot of improvements to make and within the nine months we are determined to match the world’s best practices.’

As its next stage the company will be developing a ‘Quality Management Plan’ where they would set service standards, both customer and technical. Internal and external measures too will be defined.

McKenzie says ‘now we are ready to tackle problem areas and define corrective and preventative action in a “Quality Improvement Plan.” Corrective actions fix an existing problem. Preventive actions fix a potential problem. Both are rich sources of improvement opportunities. This is a continuous activity and therefore a “Quality Improvement Plan” is a living document, constantly reviewed and updated.