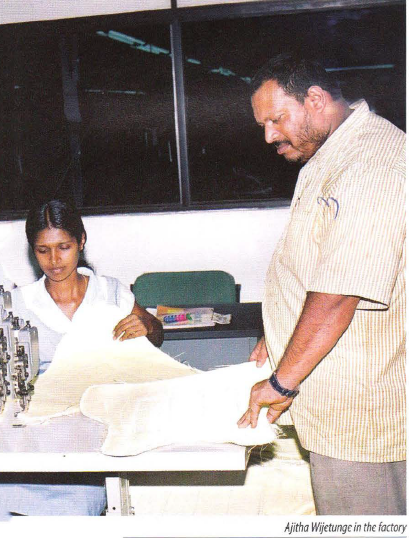

An innovative spirit, entrepreneurial vision, and the courage to face challenges, have been the building blocks of a very successful business partnership between a husband and wife duo, Ajitha and Himmani Wijetunge.

We started our business virtually from nothing. We did not receive any state patronage or encouragement. But we persisted and today we can proudly announce that we are the pioneers and the one and only manufacturer of advanced ballistic protective wear in Sri Lanka also the only manufacturer in South Asia for the uni-directional composite material, used in the ballistic industry, Ajitha Wijetunge, Chairman, Harsha International, told Sassanka Samarakkody of Business Today.

Harsha International Private Limited, established in 1992 by the enterprising Ajitha and Himmani Wijetunge, commenced the manufacture of ballistic-related body protective wear in 2000. Today, the company has grown to become the leading manufacturer of ballistic composite material in South East Asia and the ninth company in the world in this field. The definition of ‘ballistic’ is the science of projectile motion in space. “We started from virtually nothing. It was the innovative spirit of my very talented husband Ajitha, coupled with dedication and hard work on our part, that enabled us to become what we are today. When it comes to body armour, we provide from the yarn to the finished product.” Himmani Wijetunge, who is Managing Director of the company, said. “I am glad to say that my husband and myself work very well as a team. He is the brains behind the operation, with his creative talent, knowledge and innovative skills. I handle the administration, marketing and public relations part of our business.” She says the objective of the company is to manufacture a high quality product of international standard at a lower cost. “I can say without any hesitation that the body armour we manufacture is far superior in quality to the current Indian product and also cheaper in price. That is a fact, as recent field firing tests have clearly proven over and over again.”

The mission of the company is “to set up a pioneering industry to produce hi-tech life saving garments and accessories, ensuring technology transfer to Sri Lanka, thereby generating employment opportunities, creating and adding value locally, saving valuable foreign exchange.” Ajitha Wijetunge is a visionary entrepreneur and proudly claims that he initiated this industry in Sri Lanka without any state patronage or encouragement. What motivated him to peruse knowledge, and acquire develop technology indigenously and to produce protective wear locally, were the manipulations by a limited number of multi-national suppliers and their local commission agents at procurement to the Defence Establishment. “We proceeded to set up this pioneering industry in Sri Lanka amidst international pressure, such as patent issues, lack of technology and raw materials, as well as against manipulations by interested parties,” he said. Ajitha is a Marine Engineer by profession and counts 20 years in the field. He considers ballistic engineering more of a passion than a business and studied ballistics in the USA and UK. He was exposed to ballistic industries in Taiwan, China, Malaysia and Hong Kong over a period of five years.

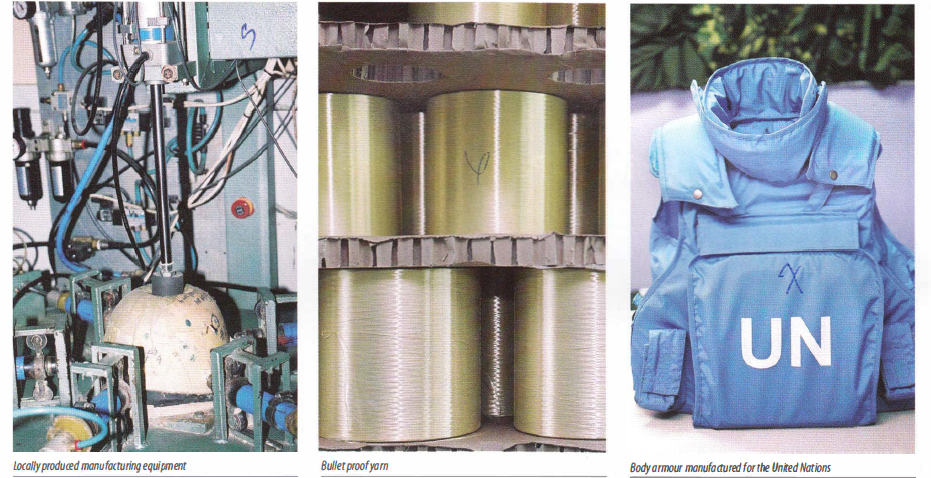

“Most of the machinery, tools and moulds are locally fabricated and designed. We make the maximum use of locally procured raw materials as well as local skilled labour and expertise.”

Through intensive research and trials conducted personally by Ajitha Wijetunge for nearly five years, he developed the latest technology of Ultra High Molecular Weight Polyethylene for the manufacture of heat moulded hard armour plates, using Thermo Plastic Resin and Engineering. He invented and introduced the Aramid Ballistic Helmet in Sri Lanka for the first time. “Most of the machinery, tools and moulds are locally fabricated and designed. We make the maximum use of locally procured raw materials as well as local skilled labour and expertise.” The manufacturing processes and production facility is ISO 9001 :2000 certified and the company is registered as a manufacturer under the Ministry of Industries.

The certification is specifically for the manufacture of Military Uniforms, BDU Combat Suits, Ballistic Related Body Armour, Flak Jackets and other military related clothing items. The product quality is tested and certified by recognised specialists that include H P White Laboratory Inc. of Maryland, USA, and Australian Ballistic Laboratory (Pte) Ltd. The products also comply with United Nations and NATO specifications for ballistic protective wear. Since 2003, the company has manufactured and supplied ballistic protective wear required for humanitarian work undertaken by the United Nations agencies in the North and East. In 2005, it installed Ballistic Anti-Mine Blankets, which prevents loss of life due to landmines, in vehicles operating in the conflict areas. “We are proud to say that we are the only manufacturer in the developing world to have been awarded contracts by the United Nations for the supply of Ballistic Protective Wear armouring and installing ballistic blankets in their vehicles. We are very much grateful to them for giving this golden opportunity to us. “In early 2006 we manufactured and exported De-mining Jackets to Jordan and recently we have received a valuable order from Saudi Arabia, where most of the leading manufactures of the world took part in the tender (actually 22 manufacturers). They ultimately selected our product,” Ajitha Wijetunge said.

Harsha International commenced supplying body armour to the security forces in 2001. According to Himmani Wijetunge, due to the very nature of their business, they had to face numerous hurdles when procuring orders, especially from the defence establishment. She spoke passionately about the corruption among those entrusted to procure military requirements. “I can fearlessly say, from my personal experience, that there is a high degree of corruption within a section of the security establishment. These elements, who hold very senior positions, are only interested in the dollar commissions they receive from arms dealers. They tried their very best to prevent us bidding for tenders. “We had to fight every step of the way. But somehow, finally, we managed to win, because we succeeded in proving that our product was of high quality, but lower in price than the imported product,” Himmani said. She added, “To give you an example, in May 2005, we bid for a tender to supply body armour to the Sri Lankan Army exclusively from local manufacturers. However, certain senior officials in the Ministry of Defence and SL Army responsible at the time for military procurement, wanted to accept the offer given by a ‘pseudo manufacturer’ who happens to be a leading private sector arms importer, representing a foreign manufacturer,”

According to Himmani, the imported product was of a lower quality and was primitive in technology while being costlier than our product. “They were deliberately delaying the tender procedure in order to push us out. The reason was, of course, the prospect of personal earnings in foreign exchange, against no benefit to a local manufacturer! But we did not give up, we applied pressure and proved that our product was far superior in quality and value for money, and finally the tender was awarded to us in January 2006 – after nine months. “In our business, we are dealing with precious lives; that is why we give a full quality guarantee. With the election of the new government, things are improving. We of course have no political party affiliations. We only want justice to be done. “We hope and pray the war comes to an end and peace dawns soon. As for our business, the orders may obviously reduce if there is peace, but still they need our services because the military has to be geared to face any eventuality. Also there are a number of local organisations and international agencies, such as the UN, who require our products.

“We are also looking at the international market.” The future objective of this brave business couple is continuous process improvement, which they believe is the key to the company’s competitive edge, in producing 100% Sri Lankan made ballistic protective wear of international standard. They concluded by saying that there were many who have helped them in their long and arduous journey. However, they are especially grateful to Dr PB Jayasundara for assisting, promoting and giving a helping hand to Body armour manufactured for the United Nations develop an indigenous industry and for Deshamanya Dr Lalith Kothalawela, who came forward with the finance through Seylan Bank Limited, Development Finance Credit Department, for their continued support and for the confidence placed in them. Ajitha believes in what President J.F. Kennedy said,” Ask not what your country can do for you, but what you can do for your country.” “In this regard I have done my part up to the best of my knowledge and ability to safeguard the precious lives of our soldiers to the maximum.”