Drip Irrigation sometimes referred to as trickle irrigation, consists of laying low-density polyethylene (LDPE) tubes of small diameter on the surface or subsurface of the field or in greenhouses beside or beneath the plants. Water is delivered to the plants at frequent intervals through small holes called emitters located along the tube. Emitters can be presented as integrated driplines also called as inline drippers (welded to the inner layer of the pipe at pre-designated intervals) or on-line drippers (fixed on the external surface of the pipe). Drip Irrigation provides maximum control over environmental variability, and it is the most efficient water and nutrient delivery system for growing crops. It delivers water and nutrients directly to the plant’s root zone, in the right amounts, at the right time, so each plant gets exactly what it needs, and when it needs it, to grow optimally. It enables farmers to produce higher yields while saving on water and fertilizers, energy, and even crop protection products.

By Wicky Wickramatunga.

Drip Irrigation is the best means of water conservation. Generally speaking, application efficiency is 90-95 percent, compared with sprinklers at 70 percent and surface (flood, border, furrow, or basin) irrigation at 60 percent at best, depending on soil type, level of the field, and how water is applied on the surface. Drip Irrigation is strongly recommended for open field crop production, and it is replacing surface irrigation where water is scarce or expensive, the soil is too porous or too impervious for gravity (flood or furrow) irrigation, land leveling is impossible or very costly, water quality is poor, the climate is too windy for sprinkler irrigation, and where trained irrigation labor is not available or too expensive.

Many types of Drip Irrigation systems have been developed. Row lengths may vary from several meters on a mountainside to a thousand meters on level land. Row widths can range from one meter or less in row crops to six meters or more for orchards. The irrigation water may be relatively clean, maybe drawn from open ditches with large amounts of impurities, or come from sources with high salinity. In certain areas where Drip Irrigation is employed, water allotments may be insufficient to irrigate all the land by conventional methods. In some places, crops depend entirely upon irrigation, and in others, crops require only supplemental irrigation.

Along with reduced water use, Drip Irrigation reduces power requirements compared to sprinkler irrigation. A typical system operates at the main line pressure of approximately 1.4 to 2 atmospheres (20-30 psi). Less pressure means reduced energy for pumping. Since Drip Irrigation requires approximately half the water compared to other irrigation methods, soluble salt concentration will also be halved. Applying water along the plant row directs the salt away from the plants’ root zone towards the furrows, as opposed to furrow irrigation where salts are pushed into the root zone. Rain or heavy irrigation then washes the salts out of the soil profile. Since the irrigation water is applied directly to the plant row and not to the entire field as with sprinkler, furrow, or flood irrigation, weed growth is reduced. Because the furrows remain dry, a farmer can quickly enter the field with labor or tractor equipment for spraying, cultivation, or harvest. Placing the water in the plant row increases the fertilizer efficiency since it is injected into the irrigation water and applied directly to the root zone. Plant foliage diseases may be lessened since the foliage is not wetted during irrigation.

The only disadvantage of drip irrigation is the initial cost of equipment per hectare or acre, which may be higher than other irrigation systems. However, these costs must be evaluated with the expected yield enhancements and through comparison with the expenses for land preparation and continued maintenance often required by surface irrigation. Land leveling and canal and drain digging require considerable expenditure. Drip Irrigation requires a higher level of management, not only to operate the drip system, but also to maintain the fertilizer injection equipment and to keep the system properly flushed. Maintenance of good filtration is an absolute must since the small openings in a drip system can be clogged.

FIELD LAYOUT

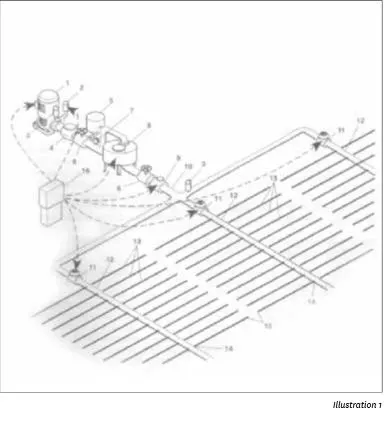

Basic equipment for Drip Irrigation consists of a pump, the main line, delivery pipes, manifold, and drip laterals or emitters. The head, between the pump and the pipeline network, usually consists of control valves, couplings, filters, timers, fertilizer injectors, pressure regulators, flow meters, and gauges. Since the water passes through very small outlets in emitters, it is an absolute must that it is screened, filtered or both before it is distributed in the pipe system. A typical drip system layout is shown in Illustration 1. If the drip line is buried, the ends of the line should be connected to an additional submain to facilitate flushing the lines. This is necessary because the drain flush valves are designed for the surface installation of the drip tube.

Illustraion 1

1 Pump

2 Pressure Release Valve Riser

3 Air Vents (Release Valves)

4 Check Valve

5 Fertilizer Injector or Tank

6 Mainline Valve

7 Pressure Gauges

8 Filter

9. Flow Meter

10. Main Line

11. Field Control Valves (Manual or

Automatic)

12. Submains

13. Drip Laterals

14. Submain to Dripline Connection

15. Drain/Flush Valves

16. System Controller

CHEMICAL &FERTILIZER INJECTION EQUIPMENT

To obtain the optimum benefits of a drip irrigation system, fertilizer (and sometimes chemicals) should be conveyed through irrigation water to the root zone of the crop. Adding fertilizer or chemicals to irrigation water is called fertigation or chemigation. There are four ways to introduce fertilizers or chemicals into a drip system. These are injection pumps (operated by electricity, gasoline or diaphragm and water-powered), venturis, pressure differential tanks, and gravity. However, the most accurate and the currently used method is the injection pumps. All injection pumps require energy to run. In remote areas where electricity is not available, gasoline engines and waterpower may be used. Piston and diaphragm injection pumps are available in various water- powered configurations. However, in irrigation systems installed in greenhouses, water- powered or fully computer-controlled dosing equipment is used to obtain a high level of precision.

FILTERS

The filtration system is the heart of the drip irrigation unit. Media filters are tanks, which contain a sand filter bed. These filters are used when the water source is an open or surface one. Media filters are installed as pairs of sand-filled containers. They can be backflushed to clean themselves easily. The need to clean or flush the filters can be determined by the loss of pressure through the filter. Therefore, pressure gauges on either side of the filter are necessary to indicate a loss of pressure and the need to clean or flush the filters. However, the necessity of using media filters has been minimized for most cases by using modern disk filters and screen filters, which have been designed to be highly efficient.

PRESSURE REGULATORS

The use of pressure regulators on the Drip Irrigation system is needed to maintain the required minimum and maximum pressures for the drip tube’s efficient function and avoid any chances of rupturing due to high pressures.

MAIN AND SUBMAIN LINES

Main lines may consist of underground PE, PVC Pipe, or above-ground aluminum pipes, most common nowadays is the PVC. For the submain line, it is common to use ‘lay flat’ polyethylene hoses or high-density polyethylene (HDPE) pipes.

DRIP LINES AND EMITTERS

From the submain, the irrigation water flows to the laterals or drip lines, which can be either polyethylene drip hose with online pressure compensated or non-pressure compensated drippers or pressure compensated or non- pressure compensated integrated driplines with in-built drippers.

There are many types of drip emitters. All emitters are designed to reduce the outflow of water to a trickle or drip. Drip tapes or tubes are used most often on row crops such as vegetables and sugarcane. The tubing is shipped flattened on a roll. Most tubing is black polyethylene, 4 -15 MILs (100-375 Microns) thick, with emitter holes at pre-set intervals of 15-150cm. In general, the more sandier the soil, the closer the distance between emitters. A 30-cm spacing is most commonly used in vegetable production. The turbulent flow design in the emitter integrated into the drip tube has larger passageways, which are less likely to clog and provides a more uniform discharge of water on undulating terrain than tapes with conventional laminar flow designs. On-line drippers, Pot drippers, Pressure Compensated Drippers, and Compensating Non- Leakage Drippers are some of the online dripper (emitter) types used in orchards, where dripline tubes or tapes cannot be used.

DRIP IRRIGATION SCHEDULES

Drip Irrigation and fertilization schedules vary with location and crop. With every irrigation, only a small amount of water is applied as needed by the plant, often daily or even more frequent basis, especially in greenhouses. This ensures more economical use of water while obtaining maximum plant production. As the plant grows, it requires larger quantities of water because root systems become more extensive, and more foliage growth is present. Therefore, water needs are increased as the growing season progresses, especially during dry, hot weather periods.

INCREASE IN CROP YIELD

Through Drip Irrigation, both water and fertilizer can be applied on a timely basis, and thereby plant stress is minimized, and yields are maximised. Since Drip Irrigation uses less water than furrow or flood irrigation, more hectares can be watered with the same water supply. The system’s success is mainly due to its ability to deliver water and nutrients in precise amounts and at controlled frequencies directly to the plant’s root zone and thereby increase crop yields by anything from 35 percent to 200 percent.

WORLD STATUS

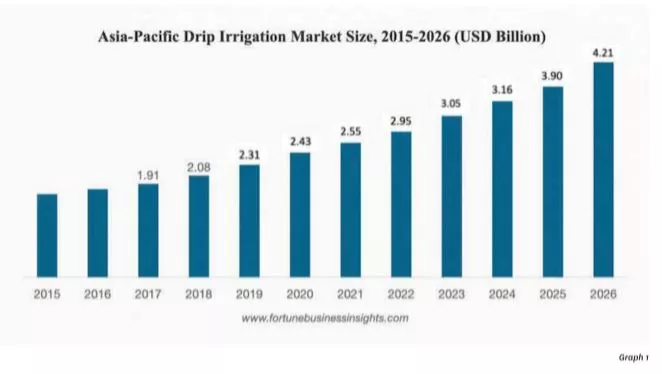

Since 1960s, Drip Irrigation has changed the method of irrigating crops in many developed and developing countries in the world. From the time the system was invented by Israeli agri- technologists, it has seen only a dramatic growth in the world irrigation equipment market. The global drip irrigation market size was valued at USD 4.63 billion in 2018 and is projected to reach USD 9.37 billion by 2026, exhibiting a Compound Annual Growth Rate (CAGR) of 9.30% during the forecast period. Graph 1 shows the Asia-Pacific Market Size. Many developing countries have become acquainted with drip systems and learned how to use them. Israeli companies have predicted that when China and India start using drip systems to their full potential, together, they could be worth the same as all the rest of the world. They have seen tremendous growth in these two countries during the last three decades. The Governments have well supported the growth by introducing excellent subsidy schemes, especially in India.

STATUS IN SRILANKA

In 1996, commercial level Drip Irrigation systems came to be established in Sri Lanka when this writer brought in the world’s largest Drip Irrigation company Netafim of Israel, to Sri Lanka on a commercial platform. Until then, a few entrepreneurs have brought in a number of systems, but the technology never took off the ground in a commercial scale. Although a quarter of a century has passed since the introduction, the growth of the Drip Irrigation market in the country has been sluggish, and the farming community has not accepted the technology due to a number of reasons.

Selection of Systems : This is the key to success. The irrigation system has to be designed to suit the individual plot of the farmer, and therefore, every system has to be custom designed. Although this is a cumbersome procedure, it has to be done for the sake of the successful operation of the system. Many factors such as the water quality, EC, soil type, source and available volume of water, rate of re-charge (if it is an open well), crop factors, rainfall, and Evapotranspiration (Et), wind velocity are taken into consideration, when a drip irrigation system is designed to suit the needs of an individual plot of a farmer. Regrettably, none of the companies involved in supplying and installation of Drip Irrigation systems follow these basics today. Ironically, state-sponsored agricultural projects too promote substandard systems at farmers’ level.

Depending on those factors, a hydraulic design is made, including a correct filtration system (which is the heart of the system), regulators, on-line or in-line drippers, fertigation method, the proper size of main, sub-main, and lateral pipes (either PVC or HDPE). Finally, the installation technician has to carefully study the design and install it in the field using his knowledge. Therefore, when selecting a suitable Drip Irrigation system, it is of vital importance to look for the capabilities of the suppliers to make an appropriate design.

Selection of Farmers : For the program’s success, this is one of the most important aspects. If the selected farmer is not interested to use modern technology, however good the system is, he is not going to make use of the same for some time until an innovative farmer in his area obtains better results by using a similar system. Therefore, it is very important to select “early adopters” in a new area when selecting farmers for introducing irrigation systems. “Open days” should be conducted wherever possible using the selected farmers’ operations as demonstrations.

Innovative Technology Coupled with Proper Use : Drip Irrigation systems can deliver incredible results if used properly. Therefore, it is vital to train the farmer (end-user) to use the system most efficiently. Especially where farmers are totally new to the use of these systems, it is vital to introduce a well-trained agronomist cum technician to guide them to obtain the maximum benefits of the system. This guidance should include agronomic aspects as well. His duty should be to give the farmer advice on specific crop recommendations, adaptation of the crop spacing, other cultural practices to suit the Drip Irrigation system, using the best fertigation method to get the maximum benefits of the fertilizers. This is in addition to guiding the farmer on proper maintenance of the irrigation system. Hence the requirement of an agronomist cum technician. A good agronomist can easily train farmers (end users) to do the maintenance of irrigation systems.

Marketing : Since the proper use of modern irrigation systems, especially Drip Irrigation systems, can bring about unexpectedly high yield levels, it is vital to explore the possibility of introducing proper marketing channels to farmers who use the technology. In addition to this, it is very important to bring about an attitude change among them. There should be a mechanism to show them that the increased productivity means a decreased cost of production. Therefore, they should be willing to market the produce at slightly lower prices than the prevailing market prices to penetrate the market effectively. They will also obtain better quality produce, which will have an edge over the produce coming from conventional farms to the market. This should be a prelude to orient them towards commercialisation of agriculture in Sri Lanka, which is the only practical way to survive in the competitive and fast globalizing agricultural commodity market in the world.

Without the above-explained guidance and training, any program to introduce Drip Irrigation systems to small-scale farmers will not have desired results and probably lateral pipes of the irrigation systems can end up on tree branches (as seen on several occasions) within a matter of months, if not for weeks after installation.

Farmers will revert to their traditional irrigation methods while blaming the Drip Irrigation technology for their failure. This will have adverse effects on the introduction of modern technologies in the long run.

CONCLUSION

In a situation where the available land area for food production is constantly diminishing, it is of paramount importance to increase crop yield per unit area of available land. This could be achieved only by adopting technologically advance agriculture, which can contribute to the efficient utilization of agricultural inputs. In most parts of the country, recurring droughts have brought down crop yields, and irrigation water is insufficient for conventional irrigation methods such as flood irrigation and furrow irrigation. The only answer to this problem is Drip Irrigation. Drip Irrigation can reduce the Cost of Production (CoP) of any agricultural crop by increasing the productivity per unit area of land. During a demonstration conducted recently, it was found that drip irrigation could produce thrice as many tomatoes than furrow or flood irrigation using a lesser amount of water. Another example, as published in the Tea Research Institute’s Annual Report of Year 2000, a trial plot of Drip Irrigation and Fertigation on four hectares of tea was conducted by the institute in 1998/99. A phenomenal yield increment from 2,557 kgs of made tea per hectare in the control plot without fertigation to 6,058 kgs per hectare in the fertigated plot has been achieved in the trial. Therefore, the authorities should focus their attention in introducing proper and advanced agricultural technologies, including Drip Irrigation/ Fertigation on existing cultivated lands rather than attempting to increase the total cultivated area by clearing shrub jungles.

It is well-known fact that the cost of production of many food items in Sri Lanka is much higher than that of many neighboring Asian countries. This situation creates calamities in the local market when imported food commodities are brought to the market at very low prices. As an effective method of reducing the cost of production, Drip Irrigation has played a vital role wherever it has been introduced. Therefore, Drip Irrigation can play a vital role in future agriculture in Sri Lanka, especially in increasing productivity, if successfully introduced.