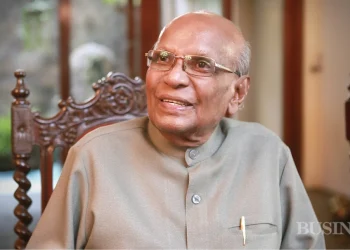

Athula Weerarathne, Founder/Chairman, Elcardo Industries is an innovator, entrepreneur and a risk-taker. With his revolutionary vision, Elcardo Industries was established in 1985 and continues to manufacture innovative products. The Chairman speaks about the performances of Elcardo since its infancy, and discusses the requirements necessary to build a strong brand presence. He stresses the need for a skilled and professional workforce in the manufacturing industry.

By Gayathri Kothalawala

Photography Vishwathan Tharmakulasingham

What inspired you to venture into this industry?

I have always been passionate about manufacturing. Immediately after I left school, I went overseas to study manufacturing in Japan, Taiwan and other countries in the region. The programmes of study that I followed served to expand my knowledge on steel manufacturing. I returned to Sri Lanka in 1984 and in 1985 set up my own company, Elcardo.

Can you tell us about the progress Elcardo has achieved since its inception?

I started the business with three staff members. I always thought of ways to manufacture with innovation rather than trading. This has played a large role in the company and we introduced products that were very unique to the Sri Lankan market.

We began manufacturing crash bars, also known as bull bumpers. However, about two years into our operations, the Government implemented a regulation that banned crash bars citing safety measures. Therefore, we ceased that line of manufacturing.

Thereafter, Elcardo focused on manufacturing stainless steel silencers. We had the honour of being the first Sri Lankan manufacturer to introduce stainless steel silencers. While our competitors offered GI and steel silencers, Elcardo was able to offer a product with higher durability together with a warranty period of five years.

I was always looking to introduce a product to the market that did not exist before and in 1995, we started to manufacture rolling doors and shutters in Sri Lanka for the first time. The products were being imported to Sri Lanka before our entry into the sector. We began to assemble the products domestically using Taiwanese machinery and sheets imported from Australia. Our manufacturing capacity has expanded over the years and the product portfolio at Elcardo currently offers about 95 per cent of door accessories manufactured in Sri Lanka.

“My Idea Is To Provide Total Building Solutions Under One Roof For Customers’ Convenience”.”

Our association with the automobile sector didn’t stop with silencers and crash bars; we import and distribute automobile accessories for four-wheel drive vehicles such as Toyota, Nissan, Mitsubishi and Isuzu.

Further developing solutions for the construction sector, Elcardo started manufacturing C purling, which we introduced as a solution to the scarcity of timber in Sri Lanka. The product offered an alternative to importing timber for the construction sector. We also manufacture Swing Gates, Sliding Gates, Roofing Sheets and Gutters. My idea is to provide total building solutions under one roof for customers’ convenience.

Today, Elcardo has over 1,500 employees; over 3,000 micro and SME level entrepreneurs are employed indirectly and 12 outlets supply Elcardo products to customers throughout the island. In addition, we have six factories; while three are located in Colombo, the other three are located in Kandy, Matara and Kurunegala.

We have also expanded beyond Sri Lanka to export Elcardo products to India as well as the Maldives.

Have you introduced any new products to the market?

Two years ago, Elcardo for the first time in Sri Lanka, began to manufacture a substitute material for timber using 90 per cent Sri Lankan sourced materials. This Wood Plastic Composite (WPC) board uses chemicals and recycled materials in the production. It is water resistant and prevents damages incurred from insects. WPC is simply an alternative for wood. The product comes with a warranty period of ten years and can be utilized for a variety of purposes such as flooring, skirting and other decorative needs.

Elcardo added stainless steel pipes to its portfolio last year. This year, we began manufacturing GI pipes.

Earlier this year, we began to assemble solar systems in Sri Lanka by importing the inverters and panels from Australia. We now offer the product as well as installation services to residencies, apartments and hotels.

We Began To Assemble Solar Systems In Sri Lanka.

Using Stainless steel fabrications, Elcardo offers pantry cupboards and other kitchen related products to the hospitality sector as well as individual residences. Our well-motivated engineering and architectural teams are able to design and fabricate kitchen appliances such as stainless steel pantry cupboards per the csutomer’s requirements.

In terms of future products, construction for a new factory is underway in Welipenna. There, we plan to develop a product similar to the WPC board. The Ecoboard uses recycled materials, which include hay dust to manufacture a product that is durable. At the same time it is designed to be impervious against water and insects. These qualities make the Ecoboard ideal for ceilings and pantry cupboards.

Can you elaborate on how Elcardo faced challenges?

The major challenge that Elcardo as well as the industry face is the scarcity of labour. The potential labour force tends to gravitate towards three-wheelers. Therefore, industries are unable to find skilled professionals. As you embark upon a new production, the scarcity of labour can affect the production process drastically.

However, there are talented, hard-working youth interested in the industry, and Elcardo offers attractive remuneration that appeals to them. We invite enterprising individuals from rural areas, and provide them with accommodation and training. Once they are accustomed to Elcardo’s production process, they become valued employees. We have also retained long-time employees who have first joined the company in the 1980s.

A significant challenge that manufacturers face as a whole is competing with the multinational products. This has become very difficult due to the import duty rates that are imposed upon the industry and has to be considered in a logical manner. At present the import duties imposed on completed items are secondary to the duty on raw materials imported to manufacture the same items.

Another challenge is the change in technology. We constantly update ourselves by researching the latest trends in the global market and investing in state-of-the-art technology. Whenever an innovative concept has been introduced internationally, we seek to introduce the same to the Sri Lankan market.

What are the key qualities that a company must cultivate in order to build a strong brand presence?

Within Elcardo, we have ensured that our employees have a positive and productive work environment. We constantly provide them with motivational programmes to ensure a unique corporate culture. To provide a quality service to the end customer we must keep our employees happy and focused. Thus, the operational system will run smoothly.

Instead Of Waiting For The ‘Right’ Time, Focus On Offering A Product That Is Manufactured Properly And Ethically Without Deceiving The Customers. Do The Right Thing The Right Way.

In order to create a strong impression about the company among customers, we ourselves have not invested heavily on publicity. Rather, Elcardo has taken special efforts to maintain our service. The manner in which the customer is taken care of once a service is provided and how our products perform are factors that contribute to reassure customers.

The backbone of Elcardo is our precious employees; whenever an employee faces difficulties the company assists them. Elcardo adopts a family orientated corporate culture within the organisation. From this year onwards, we offer a wholesome meal to our employees. The management has a healthy relationship with every employee, from the smallest position to the most important, where each member is treated equally.

Who has aided you in this journey?

Behind my success, I have a very powerful team in the Elcardo family, committed to the company and myself and I am thankful to them. My wife, who plays a crucial role in the financial aspect of the business, allocating financial resources strategically to each business project prudently. The second generation – my two daughters and son- has begun their work under the guidance of my wife and I. Further, without our customer base we would not exist. As a mark of gratitude, we will continue to provide them with the best service.

What can you tell us about the industry as a whole?

As an industry, our biggest competition comes from imported products available in the market. The Sri Lankan manufacturers are currently discussing how to tackle the issue.

I see the entry of new domestic players into the market as a very positive improvement. There should be new players to create a competition, which motivates the industry to excel.

What is your advice to the aspiring Sri Lankan entrepreneurs?

There is no ‘right’ time to begin a business. There are innovative ideas to explore. Consequently, imitating an existing idea is redundant and creates unnecessary competition. Innovative concepts are regularly introduced in the global market; you only need to research what options and avenues are open to you.

Instead of waiting for the ‘right’ time, focus on offering a product that is manufactured properly and ethically without deceiving the customers. Do the right thing the right way.

As a businessman, practice modesty and transparency, and your customers would not hesitate to trust in your product and brand.