From that modest workforce of 5 in 1927, CTC today generates employment both directly and indirectly, to approximately 300,000. people in Sri Lanka.

CTC plays a key role in the economic development of the country. The tax component the company pays to the government is 12% of the total tax revenue collected by the state annually. In 1995, CTC contributed Rs 13.9 billion to the state coffers and was able to declare a profit after tax of Rs 475 million an increase over the previous year.

In his review of 1995, the debonair Chairman of CTC, Michael Fenn, states that there had been major changes in all areas of CTC’s business during that year. The company while looking at ways of increasing productivity has also been looking at ways of increasing the quality of the product. In 1995, modernisation of the factory was progressed with a sum of Rs 156 million being invested towards this end. “We had to improve the whole way the company looked at the business in order to move it forward into the future. We were looking at investment in new machinery and to do that we had to divest a lot of our non-core assets and non-productive assets.”

New machines also needed skilled people to operate them, so with the process of restructuring underway, CTC places emphasis on upgrading the competency levels of all levels of staff, the strength of which is approximately 1225. In support of the goal, formalised technical training commenced for operatives and technical personnel. These efforts were supplemented by exposing all levels of staff to training programmes in overseas environments. VP Malalasekera, Director CTC says,”even our operatives are sent abroad. We send them to various parts of the world to acquire new skills. It’s not limited only to management or executive staff, but at factory level we have sent our people out, which I think is a new concept in this country.”

CTC quite rightly believes that their focus on staff development will ultimately support their aim of meeting international standards in the quality of products and services. According to Fenn, “One of our strategic imperative is to have top class players and we have had that here at CTC for a couple of years or so. We’ve got to grow our talent throughout the organisation.”

CTC’s human resource development strategy has several other programmes, including a fresh approach to graduate recruitment and training.

CTC also undertook several new initiatives in 1995. One of them, the signing of the Collective Agreement between the management and the unions is considered a historical milestone in industrial relations. Says Fenn, “It was a productivity-linked pay agreement and the workforce has accepted part of that, as an aspect of teamwork. At the same time of the Collective Agreement, we also brought about a profit-related pay scheme for our workers, whereby if the company achieves certain profit targets, a portion of the profit is also paid to the workers. The signing of the Collective Agreement with the unions is definitely a benchmark achievement, particularly in a countrywide environment where productivity is low. This success was achieved through mutual trust, teamwork and commitment to a single-minded corporate objective.

Commenting on the proposed Workers’ Charter, Fenn says, that one has got to strike a happy balance between the management and the workers, “that means one has got to explain the realities of business to your workers and if you do that in such a way as we have done, I think you can reach a very healthy and mutually beneficial relationship between the management and the workforce. I think we have proven that here at CTC”, confirms Fenn.

Another new initiative CTC undertook during 1995 was the successful relaunch of the John Player Gold Leaf in its new international pack. For CTC, this was a significant milestone and an ac knowledgement by its parent company BAT (British American Tobacco) of the world class, international standard cigarette that is produced in Sri Lanka.

CTC has also given productivity a new dimension by moving into an open-plan office environment to make better use of common facilities and space, “we did away with the old oak-panelled offices, we did away with the sort of ‘guardians at the gates’ so that nobody could get through to anybody. Now we are all sitting together and departments can talk a lot more to each other and the management is available for anyone to talk to”, explains Fenn.

It’s an accepted fact that CTC is by far the largest contributor to the state coffers by way of taxes. Answering a question if this was the main reason why CTC’s products were so highly priced Fenn responded, “Well yes. We contribute 12% of the national revenue and a vast majority of that is generated by excise payments. So if you look at a packet of Gold Leaf (Rs 85/- per 20 pack) for example, 75% of what the consumer pays goes to the government. The remaining ‘bit’ is our part with which we’ve got to pay for the leaf, we’ve got to manufacture the cigarette, we’ve got to pay our salaries, we’ve got to sell it into the supply chain where the distributors have got to cover their cost and make a profit and the retailers as well. So, that’s all out of the 25% of the price. So, the real element that is making the high prices here in Sri Lanka is the excise element and that is why our cigarettes are so expensive here in this country”.

CTC’s export of cigarettes and leaf recorded a strong performance in 1995. In fact, this area of CTC’s business has been growing year after year. The main market is in the Middle East where there’s a large expatriate community, says Fenn.

The most recent subsidiary to be launched was CTC Leaf Exports -a BOI Company. The Company’s other subsidiaries are CTC Eagle Insurance Company Ltd., and CTC Foliage Ltd.

Commenting on the production and export of tobacco leaf Fenn says, “Growing tobacco is subject to the vagaries of the weather. Last year, around Anuradhapura, we suffered a great drought so our crop wasn’t as high as we expected. But the quality of that crop was very high and people whot bought that crop saw that it is very good quality tobacco coming out of Sri Lanka. So, if we can fix the weather we would do a lot better.” The type of tobacco grown for the export market is called ‘Burley’ a light air-cured type which is an excellent filler acceptable to many foreign buyers.

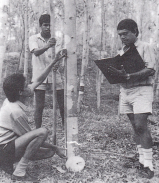

Tobacco is grown in the intermediate zones in the mid and up- country as a ‘Maha’ crop and in the low-country as a ‘Yala’ crop. Tobacco farmers receive many benefits from CTC. These include agro-chemicals on credit, loans for cultivation either from the company or arranged from banks, technical know-how regarding cultivation and curing of tobacco is also provided by CTC’s field staff. There are two main types of tobacco grown in Sri Lanka Flue-cured and Air-cured. The latter is grown primarily for export.

Having developed tobacco cultivation to a position where it has become a lucrative cash crop to the small farmer, CTC has successfully applied the same skills and expertise to projects unconnected with tobacco. “We infuse about Rs 350 million a year into the rural economy by way of purchasing leaf. All that goes to the farmer”, says Malalasekera.

“The real element that is making the high prices here in Sri Lanka is the excise element and that is why our cigarettes also expensive here in this country…”

Tobacco farmers are not employees of CTC. They are registered with the Company and enter into a contract at the beginning of the season to produce the crop, maintain stipulated standards and sell the cured leaf according to specified grades and guaranteed prices. Ensured of prompt payment for his tobacco, the farmer enjoys a greater degree of certainty, security and independence than is provided by most other crops. He and his family are not only sustained, they prosper. “They are a recognised entity in their local community”, says Malalasekera. At present, there are about 22,000 tobacco growers registered with CTC.

Better living standards have also been observed in the tobacco growing areas. What were once wattle and daub cottages are today brick and tiled houses. Many of them own a television set in addition to a radio cassette player, a sewing machine and a bicycle – symbols of rural prosperity.

With approximately 5000 hectares under tobacco cultivation in Sri Lanka and being a labour intensive crop the employment generated is rural, both for family units and for hired labour, particularly during planting and harvesting.

A good portion of the labour used is female. They are generally engaged in land preparation, planting, inter-cultivation and weeding, harvesting, stringing the leaf, for loading the barns and unstringing.

Being a seasonal crop, tobacco only takes up land for part of the year. The crops which follow tobacco benefit from the residue of the tobacco fertilisers and their yields generally increase significantly.”The farmers don’t grow tobacco all the year round, so the agricultural practices we have helped them with is very valid for other crops as well and we help them in deciding on which crop to grow and when”, says Fenn. According to Malalasekera a research study carried out on the impact of tobacco cultivation on other crops revealed that the expertise CTC had given the farmers had helped them to increase their yields of other crops.

The contribution CTC makes towards the protection of the environment is undoubtedly the biggest effort made by a single corporate organisation in Sri Lanka today “Tobacco, once it is grown needs to be cured and that needs a source of heat. Traditionally, woodfuel has been used to fire the furnaces. We used to use 0.1% of the wood in this country. Even though we used a very small percentage, we looked at how we could get out of using woodfuel and one of our guys developed a paddy-husk furnace” explains Fenn.

CTC has grown 1250 acres of new forests to cultivate their own requirements of woodfuel. The company’s afforestation programme has been described as ‘among Sri Lanka’s best’ in the Master Plan on forestry. The programme is carried out in consultation with the Forest Department. These forests are carefully planned and maintained and are a fine example of agro-forestry.

In addition, CTC provides the farmer with seedlings of fast growing species raised in company nurseries, “so that they grow their own wood on their own plots of land”, adds Fenn.

CTC has also introduced soil conservation methods which have turned barren hillsides into thriving, verdant means of sustenance in remote, forgotten hamlets. The company commenced its soil conservation programme in the early ’70s when conservation was identified as an essential requirement for sustainable agriculture. The emphasis then was on mechanical methods of soil conservation and CTC paid tobacco farmers an attractive subsidy, though not legally bound to do so, to build stone terraces, bench terraces, contour drains and earth bunds which were some of the measures adopted. CTC field staff provided the technical expertise. “The subsidy was paid, though not bound by law but of our own volition, only after an officer from the Department of Agriculture certified that the conservation method adopted was satisfactorily completed”, says Malalasekera.

Commenting on the latest method of soil-conservation Fenn adds, “The sort of evolution from stone terraces and contour drains. was the implementation of the Sloping Agricultural Land Technology (SALT) developed by Ray Wijewardena. This method not only conserves the soil, but adds back the necessary nutrients to the soil.

Mindful of the need to preserve the environment, CTC has begun converting curing barns into pad dy-husk furnaces in their quest for an alternate fuel to reduce wood-fuel consumption.

CTC’s search for alternate sources of energy was richly rewarded with the innovation and patenting of the ‘natural draft paddy husk furnace’. Paddy husk which is a disposable waste is now used in all barns in and around paddy growing areas. “This reduces farmers’ costs and simultaneously solves the environmental problem of disposal of the huge quantities of paddy husk”, says Fenn. Nearly 50% of all curing barns already have paddy husk furnaces installed under an ongoing programme. According to Fenn, “By the end of next year all the barns that we use will be converted to paddy husk users so we won’t be using wood. fuel”, he goes on to add, “CTC is very much aware of its position within society and we have very clear objectives to be seen as a good corporate citizen and to put back into the environment what we take out of it. So we are very concious of the fact that we’ve got to look after the environment.”

For many years CTC has recognised that as a large and successful enterprise, it has a responsibility to make a contribution to community life as well. This is done by supporting a wide variety of sponsorships which help to promote sports, drama, indigenous arts and crafts. Within the arts, CTC sponsored for the second year in succession the ‘Nawa Kalakaruwo’ (New Artists) exhibition organised by the George Keyt Foundation, to promote the talent of emerging young artists and in November this year CTC will be sponsoring Senaka Senanayake’s 100th one-man exhibition, “we sponsor what we consider is necessary for the betterment of society”, adds Malalasekera.

In addition, all popular sports such as football, volleyball, rugby, cricket and cycling to name a few, have gained CTC’s constant support. Says Fenn, “we’ve been with the Federation of Football for 10 years and we’ve seen how that sport has developed with our help. Last year we even won the SAARC Gold Cup.”

CTC has joined hands with seyeral organisations to support national projects, in its endeavour to uplift the lifestyle of the people. One of them is the collaboration with the Ministry of Health and State Pharmaceuticals Corporation in the management of the Thriposha Complex, thus becoming partners in a project to combat malnutrition. “Thriposha’ is a high-protein food supplement for malnourished infants, pre-school children and pregnant or lactating mothers.

Community development projects are also regularly organised with the participation of company employees. Such programmes conducted jointly with rural development societies, designed to improve the quality of life in the villages have proved a success. “We do a lot of social-service work together with our farmers”, says Malalasekera. Recently, a children’s ward was built at the Uda Dumbara hospital with funds collected from tobacco farmers in the area.

Concluding a lengthy but enlightening interview Michael Fenn. states, “If you look at our mission. statement, we aim to be the best in South Asia and we are looking for cost/quality leadership in this region. So, I think what we will be seeing is furtherance of where we are today, in building employee commitment, in building environmental issues and in looking at what CTC can do to add back into the community. In terms of marketing we just launched Benson & Hedges. We are also very concious of what the consumer is looking for in terms of cigarettes and we are looking to ensure that we are supplying all those demands.”

Ceylon Tobacco Company Limited has certainly made its mark on the Sri Lankan economy as well as on the community. With clear objectives defined, the company is sure to maintain its premier position…….. “leading the way’.