S. Arunasalam

Productivity, a vital ingredient for advancement of an organization or a country is not one that is understood by many. S Arunasalam discusses what a key role Benchmarking can play in improving Productivity.

Productivity is a key issue in our country. However, not everybody really understands what- it is. Many equate productivity to the efficiency of our people and tend to blame our attitudes, culture, etc., for low productivity. This is a wrong notion. Productivity is influenced by many factors; people and culture are only two of them. Other factors that influence productivity, whether in an organization or in the country as a whole, are technology, organization structure, systems and procedure and business processes. All these factors at varying intensity influence productivity in each organization.

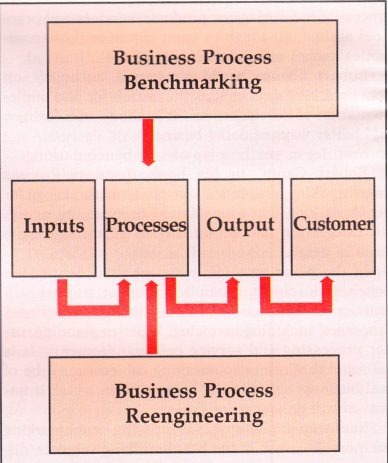

This two article series look at how two key process improvement tools, namely Business Process Benchmarking and Business Process Reengineering can play a major role in productivity improvement.

John Heap, author of Productivity Management: A fresh approach, defines productivity as the ratio of value of goods and services to cost of resources consumed. This definition does not confine itself to a single resource like labor or machinery. It looks at ‘all resources’. This eliminates a key mistake of single factor productivity measurement.

Another error in productivity measurement is the usual internal focus. Many companies’ performance measures, including the productivity measures, are internally focused. Any improvements from the previous years are highly appreciated. But they do not see the quantum leaps made by the competitors. Many have the comfortable feeling that they are doing okay.

Many Sri Lankans think that Sri Lanka has the highest or second highest literacy rate in Asia. We are not even in the first ten today. Perception is sometimes far from reality. Unless you measure and compare externally you are not going to see reality. The birth of formal benchmarking was an outcome of a similar situation. In the 1970s, Xerox Corporation, the pioneers of the photocopying technology, had about 80% of the global market share. They measured their productivity gains carefully, but internally, and it averaged at about 8% per annum. Definitely, a satisfactory sign.

However, in the early 80s, Xerox’s market share dropped to 30%. Xerox lost its share to its Japanese competitors, mainly Canon. Xerox found to its astonishment, that the selling price of Canon was equal or less than the cost of manufacture of Xerox. The first reaction at Xerox was disbelief.

Then, they decided to see the reality. They des patched a team of managers to their Japanese subsidiary, Fuji Xerox. They did a comparative study of functions and processes; how differently the Japanese did things that gave them the competitive advantage. This was the first formal benchmarking study.

Xerox defined benchmarking as ‘the continuous process of measuring our products, services and practices against our toughest competitors or those companies known as business leaders.’

Robert Camp, world renowned authority on benchmarking defines it as the search for and implementation of best practices. It is the search for new and better ways of doing business.

Now, let us see how we can do benchmarking. Robert Camp, in his book Business Process Benchmarking, presents a four-phase methodology for benchmarking. The four phases are, planning, analysis, integration and action. Let us go through each stage in detail.

In the planning stage, we must first identify the benchmark subject. It can be a product, a strategy, a function or a process. Xerox benchmarks 67 business processes, including invoicing, logistics planning, order processing and service call management. It is essential that the benchmarking subjects must be of real business value to the organization, which if improved will enhance the value.

Next step in planning is identifying benchmarking partners. For each of the benchmarking subjects, different partners could be found. Benchmarking can be internal or external, depending on the benchmarking partners. Internal benchmarking can be done among departments, business units or local and overseas subsidiaries of the organization. For example, a hotel chain could benchmark among its hotels located at different places. A large conglomerate can benchmark among its companies involved in different businesses. Though internal benchmarking will definitely bring in some benefits, the benefits will be more with external benchmarking.

External benchmarking can be done within the industry or with the best in class performers in a particular benchmarking subject. I would like to give you some real life examples of choosing cross industry benchmarking partners. You can then see how lateral thinking plays a role in benchmarking.

When Xerox wanted to benchmark its warehousing process, it chose LL Bean as the benchmarking partner. Their business is totally different to that of Xerox. LL Bean is a mail order ready-made garment seller, whereas Xerox is an office automation company. However, Xerox identified some striking similarities. Xerox handled about 500 items whereas LL Bean handled 1500. Xerox was able to process only 500 orders whereas LL Bean handled three times more than that. Xerox decided that by benchmarking against LL Bean will help to improve Xerox warehousing. And it did help.

An aircraft manufacturer wanted to benchmark a treatment process. It had to treat different sizes of metal at different temperatures for different duration. Can you guess the benchmarking partner they identified? A bakery. In this bakery, they had to treat different sizes of products at different temperatures for different duration. The process was similar.

Initially to identify probable benchmarking partners, secondary research must be carried out. Trade statistics, annual reports, benchmarking databases and business press are common sources for secondary research. Award winning companies are good candidates for benchmarking.

Last step in planning is to determine data collection methods. It is not always possible and not necessary to enlist world-class firms as benchmarking partners. For example, if you request Xerox to be a benchmarking partner, chances are that your request will be turned down. Xerox will receive hundreds of such requests every year and it will not be possible for them to accede into every one of them. And, Xerox may not have any interest in your firm unless they are convinced that they can learn from you. From your side too, it will be an expensive exercise.

Many benchmarking studies use internal and external data that are available from various sources. Your own company will have a lot of information about your key business processes. Your employees, employees of your subsidiaries, reports and memos are some sources of information. Business press will have useful articles on successful companies and their best practices. Internet is a powerful tool to get information on best practices around the globe. Many benchmarking centers provide databases and advice on benchmarking. They are relatively cheaper. An organized study into these sources will give a lot of useful information.

Direct benchmarking by enlisting benchmarking partners might be time consuming and expensive. But, it will provide direct insights into the way others do things. Structured questionnaires, interviews and site visits are the common data collection methods used.

There are now specialized software tools available to record the collected data in an organized way, so that retrieval and sharing of information will be easy. Next phase in benchmarking is Analysis.

In this phase collected data are analyzed to determine the performance gaps. The performance gap is the difference in performance of a particular process in your organization and that of the best practice identified. For example, if the order processing time in your company is three days and the best practice is half a day, the performance gap is two and a half days. Performance gap can be measured in terms of time, cost, quality or service.

Once the gap is identified, it may not be possible to close the gap completely, as there may be some factors inherent to the process in your company. But, in this stage you will be able to identify and project new performance levels for your processes.

The third phase in benchmarking is integration. In this phase, the recorded results, performance gaps and future performance levels are communicated to the employees. The process owners, the employees who carry out the process, are briefed on the best practices for that particular process and their feedback is obtained. New performance goals are agreed and set.

The last phase is action. This is the implementation phase. In this phase, action plans are drawn and the new processes are implemented. The progress is measured carefully and adjustments are made when necessary.

And the last step in benchmarking is recalibrating the benchmarks. Benchmarking is not a one-off exercise. It must be an ongoing program. It is a continuous search for new and better ways of doing things. The companies must allocate adequate resources to continue benchmarking. In many successful companies in the United States, there are full time benchmarking staff carrying out continuous benchmarking.

Many companies use consultants in their benchmarking. Initially, benchmarking was handed over to the consultants as turn-key projects. However, companies have found that more involvement of their own staff will yield more benefits. Now, the use of consultants is in the form of supportive and advisory. Michael Hammer says consultants provide three things to a re-engineering project. Heads, hearts and hands.

Heads; the knowledge and expertise that they have gathered from the past experience and specialized training. Hearts, the impassionate solutions that they can provide without any bias or personal stake in the processes or functions. Hands, the ability to mobilize skilled personnel to undertake the project.

In addition, consultants may help to enlist useful participants from their client base. In a country like ours where there are concerns about confidentiality, use of reputed consultants will help. The participants. will be more open and will provide useful and sensitive information on the assurance that the consultants will not disclose the source. This is more evident in statistical benchmarking such as salary surveys.

It is essential to clearly understand and define the role of consultants in a benchmarking program.

What should we, Sri Lankans, do?

Having embarked on a productivity drive, we should benchmark ourselves against countries, that have achieved higher productivity growth rates, to learn from them.

In Korea, the Korean Productivity Center was established in 1957 to promote and increase national productivity level. One of their successful campaign was the Double Productivity Movement, launched in 1989. It was launched with the aim of doubling their added value productivity within a five-year period. This drive was supported with promotional and training materials, advisory programs and information exchange programs.

In the United States, the Malcolm Baldridge National Quality Award, the most coveted award, requires evidence of organizational benchmarking as a condition to qualify for the award. Eight of the top ten America’s Most Admired Companies, ranked by Fortune, have formal benchmarking organizations within their companies.

In Sri Lanka too, the National Quality Awards and similar awards must have benchmarking as one of the criteria to qualify for the award.

One of the concerns that the Sri Lankan managers have is confidentiality. However, one must admit that in Sri Lanka, very few things are confidential. Benchmarking is a win-win technique. Every partici pating company will have something to learn and benefit from the others.

Large groups of companies should implement internal benchmarking as an immediate step. There are no concerns of confidentiality in internal benchmarking. Their success will inspire other organizations to follow suit and will pave the way for external benchmarking.

The trade chambers must take an active role in promoting external benchmarking and forming benchmarking associations. Formal benchmarking associations must be formed and formal links must be established with similar organizations in other countries.

Benchmarking must be promoted within the companies in the industrial estates and within the industrial estates. Quality circles within the companies should use benchmarking as an essential tool.

The writer is a management consultant at a leading international consulting firm. He is a Chartered Accountant and a Chartered Management Accountant. He is also a qualified elec tronics engineer and a Registered Marketer.