With its beginnings in 1945 under the Department of Agriculture and then handed over to the National Livestock Development Board in 1978 the Ambewela farms and factories were privatised in 2001 and managed by Lanka Milk Foods, a member of the Stassen Group of Companies. Under this new management, the production at the farms, elevated to international standards, has since increased threefold and continues to flourish and advance in quality and productivity. A recent development at the Ambewela farm – a new, technologically advanced production facility – has now begun to introduce flavoured milk, yoghurt and cheese of premium quality, to the markets.

By Prasadini Nanayakkara

Photography by Hiranya Malwatta

The Ambewela farm and the New Zealand farm in Pattipola of Lanka Milk Foods, are home to pure-bred Friesian and Ayrshire Cattle, a total of over 1,600 animals are housed at the farms. These high yielding pure-breds and imported rye grass grown at the pastures, for use as cattle feed, has resulted in an increase in daily milk production from ten litres per cow to 15-20 litres. The farms provide the markets with UHT (Ultra High Temperature) liquid milk, with its popular product, Ambewela Fresh Milk in a tetra pak of Swedish technology that preserves its freshness. This high quality milk is also exported to the Maldives as UHT packs. The cheese production is carried out as a cottage industry at the New Zealand farm where a natural cheese, Gouda has a popular demand by hotels for culinary purposes. The cheese is also sold in retail markets. The New Zealand farm is also home to 180 Dutch White Saanen goats and 600 rabbits. This breed of goat produces a high yield of milk, which is supplied as sterilised milk to the supermarkets in 190ml bottles.

Recently at the Ambewela farm a new state-of-the-art production facility has been installed under Danish funding as a turnkey project. At this plant flavoured UHT milk, yoghurt and natural cheese are produced under stringent hygienic conditions and Danish technological expertise. The new production facility employs 75 workers living in the surrounding communities and has been providing training for school leavers to run the various functions and operations of the new equipment at the plant. A complex, the new facility consists of separate buildings made for different purposes, housing new equipment of high-end technology. For instance, milk at the modern milking parlour transports the milk directly to a mixing room where the milk is subjected to a series of events, including temperature treatments, optimum storage, pasteurising, and also skimming for skim milk production. The upkeep of clean white interiors and best practices are carried out to maintain high standards of quality and hygiene. Caustic solution is circulated through the building pipelines to cleanse the equipment installed in each building and specialised ventilation systems are in place to clean the air within the facility. Even the cattle housed here are benefited by additional comforts, and open and hygienic spaces, and as a result, produces a higher yield of milk.

At this new facility, ten tonnes of natural or unprocessed cheese are produced per month for vacuum packed blocks and slices. These are Ambewela Edam and Ambewela Gouda, produced for the hospitality industry and also sold in the retail market. The plant also has facilities for packaging the flavoured milk, chocolate and vanilla in tetra paks, circumventing the need to transport milk to Colombo for packaging and instead directly transported in the tetra paks from cold room storage. Latest technology has not only been implemented here for production operations but also for producing cattle feed, where the ingredient components are mixed at optimum ratios that result in the maximum yield of milk and these conditions are successfully maintained as they are carried out by computerised operations.

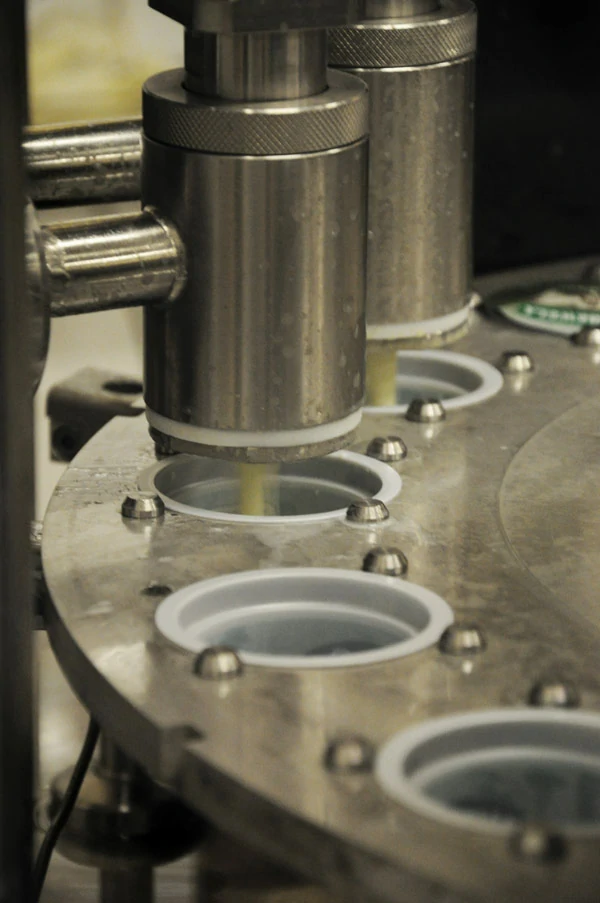

One of the newer products seen at the market today is the Ambewela yoghurt. Initially begun in small scale, distributed in the Nuwara Eliya town, its popularity quickly rose as a fast moving product due to its unique quality and is now supplied to mainstream supermarkets through the cold chain distribution. Like the other dairy counterparts, yoghurt is produced from the high quality fresh milk, with semi-automated machinery, carrying out, filling and sealing under sterile conditions to produce a premium quality product. At each point a factory worker inspects and quality checks the product to maintain stringent industry standards. At present 500,000 cups of yoghurt are produced per month with the hopes of increasing to 1 million in the coming months to meet the demands, with the installation of additional filling stations.

Outside the building complexes, lawns are well trimmed, and an impression of freshly landscaped spaciousness is instantly created. A utility building, effluent treatment plant, a plant for slurry preparation and collection where natural fertiliser is obtained are also located in the vicinity and several more buildings are in progress for additional functional purposes to further the capabilities of this new production facility. Apart from flavoured milk, yoghurt and cheese, increase in production of UHT fresh milk is expected with the new facility contributing to the production volume as well in the future. This is in order that the local market is aptly provided with rich resource of liquid milk to meet consumer demand.